Editor’s note: One of the other books we have in the works is tentatively titled: “Go, Go, Go: The Life, Influence and Woodworking of Tage Frid” by Bill Rainford. In this post, Bill introduces himself and explains a little bit about the book. Were thrilled to work with Bill on this book about Frid (1915-2004), one of the most influential woodworkers of the 20th century.

— Christopher Schwarz

I’m driven by a lifelong desire to learn, build, experiment and share. I love examining furniture to see how it was made and read the tool marks. I enjoy digging through period sources to learn a new technique or build something that has not been seen for generations. I also search out designs that take form and function into account. These inclinations can often take me down some deep rabbit holes or on crazy adventures. I wouldn’t have it any other way.

As I progressed in my woodworking I got tired of building predominantly power tool projects from magazines. I wanted to design my own pieces and get into more traditional tools and techniques. Around that time I was referred to the three-volume set of books “Tage Frid Teaches Woodworking” by the Taunton Press. This iconic set of books was eye opening. Tage’s no-nonsense approach, acerbic humor and amusing anecdotes made for a memorable read.

Many of the tenets of Frid’s teaching resonated with me and still guide my work. A core principle of Frid’s mentoring was to teach several different techniques to accomplish a given task so a student had a deeper well of technical knowledge to draw upon when the time came to use it. Long before “hybrid woodworking” was a coined phrase, Frid espoused the use of power and hand tools to help a craftsmen compete and make a living. In addition to a respect for traditional techniques and wood itself, I also appreciated his efforts to show how a craftsman should strive to make something that is functional, comfortable, tailored to the room or audience and also affordable.

My Background

I grew up on Long Island, N.Y. I’ve been a lifelong woodworker and maker. I’m at my happiest when I am out in my workshop. I started out helping my father and grandfather around the house as a child – finishing the basement, building a deck etc. I grew up watching “This Old House” and “New Yankee Workshop” and building power tool oriented projects. Once I got a place of my own I got into building things such as a custom mantel, a loft, staircase, bookcases etc. but I didn’t feel fulfilled. I wanted to get into more intricate hand work. That’s when I learned about the North Bennet Street School (NBSS), which is the oldest trade school in the United States. After taking some hand tool fundamentals and carving workshops at the school I went on to become a graduate of the two-year Preservation Carpentry program. I now develop and teach traditional woodworking workshops at NBSS, the Boston Architectural College, Historic Eastfield Village and other regional schools, conferences and events.

I consider myself to primarily be a traditional joiner, building and restoring traditional windows, doors, trim and casework though though I’ve also built a fair amount of furniture, restored timber frames and worked on historic buildings such as the Old State House in Boston, the Harvard Shaker Meeting House in Harvard, Mass., and similar properties.

I’ve written for Fine Homebuilding, Popular Woodworking, Early American Industries Association, Fix.com and my blog RainfordRestorations.com

I live in southern New Hampshire with my a wife, Alyssa, and two sons, Bradley and Henry. I’m thankful to my wife for being supportive of all my woodworking activities and for my two sons who love watching me work around the house.

Genesis for the Book

A couple of years ago I wrote up a blog post which shared my thoughts about Tage Frid and his work and wondered what ever happened to his tools and furniture. You can read that post here. In response to that post I received a comment from Tage’s grandson Oliver Frid and had the opportunity to visit Tage’s son Peter’s home.

It was an inspirational visit and they were gracious hosts to put up with me being excited to see many of Tage’s tools and furniture pieces in person. You can read more about that visit in this post. As I learned more about Tage’s life and work I realized there were a lot of interesting stories to be shared with a wider audience.

What will the Book be About?

The book will be a mixture of biography, woodworking projects with plans, interviews and an exploration of the impact of Frid’s work. From Frid’s time working for the Royal Danish Cabinetmakers (at the time Kaare Klint was running the department), to his time at the School for American Craftsmen and the studio art movement through his time at the Rhode Island School of Design (RISD) and Penland, the goal is to share projects based on Frid’s work in those periods and some by those whom he taught and inspired. It will be an eclectic mix of chairs, tables, casework, built-ins and workshop projects that explore the various forms Danish modern designs can take on in a flavor reminiscent of Frid’s aesthetic.

After working on colonial and Shaker styles of furniture and buildings for such a long time, I’ve found that Danish modern designs really appealing. I’ve been intrigued by how well Danish modern pieces can fit into a traditional home in large part due to their expressed construction, use of traditional joinery and respect for and re-interpretation of traditional forms.

Upcoming Article

One of Frid’s most-remembered projects is his traditional Scandinavian workbench with a shoulder vise, square dogs and a tail vise. It was similar to the bench I was trained on. Inspired by Frid’s design and my own preferences I built my own interpretation of this bench and made a series of modifications to address many of the criticisms folks have had with Frid’s earlier workbench. The bench I built was about 2′ longer, a few inches deeper, built up in some areas to add weight and makes use of some newer construction techniques and new easier-to-install hardware that was not available to Frid in the 1980s. If you’d like to learn more about this workbench and whet your appetite for the forthcoming book, I encourage you to check out my article in the February 2017 issue of Popular Woodworking Magazine, which is due out next month.

If you’d like to learn more about me and my explorations in woodworking, please check out my blog or follow me via my other social media accounts below.

— Bill Rainford

Twitter: @TheRainford

Blog: RainfordRestorations.com

Facebook: Bill Rainford Woodworking

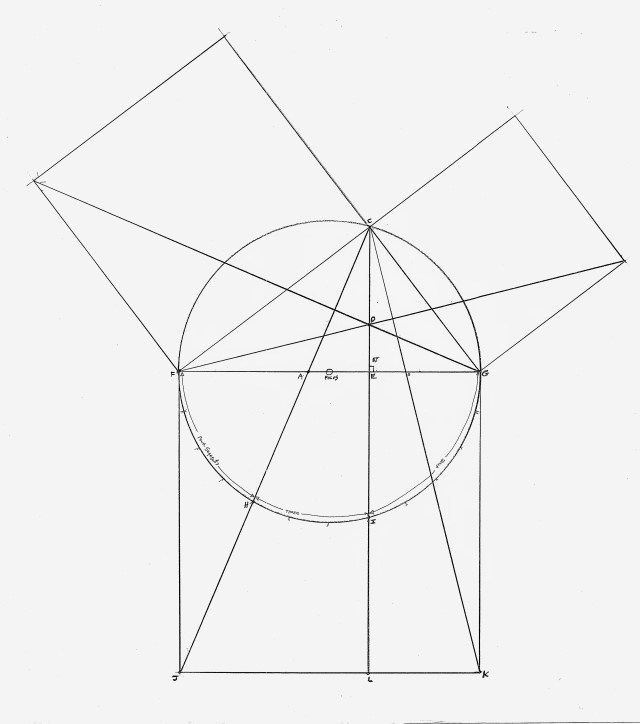

In this sketch I did of a Masonic “

In this sketch I did of a Masonic “