One of the most famous furniture makers and designers in the Midwest is someone you don’t hear much about in woodworking circles: David T. Smith. With this blog entry, I hope to change that – at least a little.

Smith is a long-time furniture maker in Morrow, Ohio, who specializes in early and vernacular American styles. Plus many woodworkers I know have worked for him during the last 40 years or been inspired by his designs.

My old boss at Popular Woodworking Magazine worked for The Workshops at David T. Smith, as did associate editor Jim Stuard and some of the other staffers who passed through the magazine. Troy Sexton, one of my favorite woodworkers, was a long-time subcontractor for Smith.

So during my 15 years on staff (1996-2011) I heard a couple hundred stories about Smith and his influence on the furniture market.

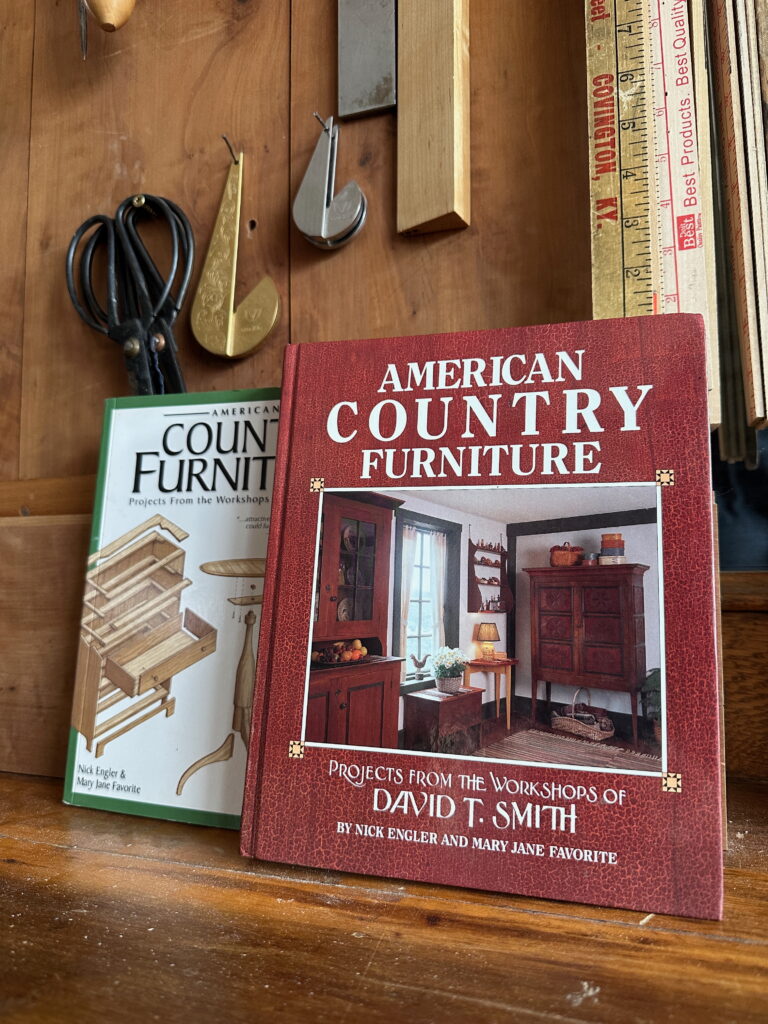

More important, however, is his book: “American Country Furniture: Projects from the Workshops of David T. Smith.” The book was originally published by Rodale Press in 1990. A newer version is available from Fox Chapel. The Fox Chapel version is printed on better paper, but they removed about 100 pages of furniture history stuff from the book, plus I think the photos are a little muddier in the Fox Chapel version.

It’s hard for me to overstate how important this book was to amateur and professional furniture makers in this area during the 1990s. Everyone had this book. Everyone except me.

So when Jim and Steve at Popular Woodworking decided to do a porringer table, I was astonished at how they came up with such a great design in short order. It turns out it was from Smith’s book (page 62 of the original edition).

I got wise. And I got my own copy of the book.

It is crammed with fantastic projects and techniques. Once I was shooting an article with Glen Huey and he built his divided-light doors in an astonishingly easy way.

“Wait,” I said. “We have to do an article on this technique you are showing me. It’s amazing.”

Glen quickly fessed up that it was from Smith’s book.

So get the book. Look past the 1990s-era printing and production values. The book was ghost-written by Nick Engler and Mary Jane Favorite at Bookworks Inc. in West Milton, Ohio. I worked with both of them for more than a decade (I was Nick’s editor). The information is fried gold.

Over the weekend, Megan Fitzpatrick and I drove to the Workshops of David T. Smith to attend its annual Festival of American Crafts. It’s been going on for 45 years now and is when Smith opens up the shops to the public. There he has a redware pottery facility, a blacksmith shop, a farm store and – of course – the furniture and finishing operations.

Plus there were a bunch of vendors selling antiques and new furniture. Plus alpacas to pet. Food trucks. And a band to entertain visitors. Smith himself was there, too, talking it up with customers and chatting about kitchens and furniture.

As Megan and I left the festival on Saturday, it struck me that I rarely hear many people mention his name or his book. And as I paged through the book this morning, I also have to admit that this book was a huge influence on me and stoked my love for vernacular pieces. And the designs have aged well during the last 35 years.

So let the record show: David T. Smith is someone I think you should get to know.

— Christopher Schwarz