Part 1 is here.

MACHINIST: Are you not painting altogether too gloomy a picture? That the machine has largely taken the place of handwork is true so far as the trade is concerned. There are not many shops left where handwork is practicable at all (though I know of several good woodwork shops where it still holds its own). But it is not of the trade I am thinking. I have in mind that body of men which the WOODWORKER represents; men who do woodwork in their own homes, and who do it purely for the love of the thing. To them handwork is as alive to-day as ever it was.

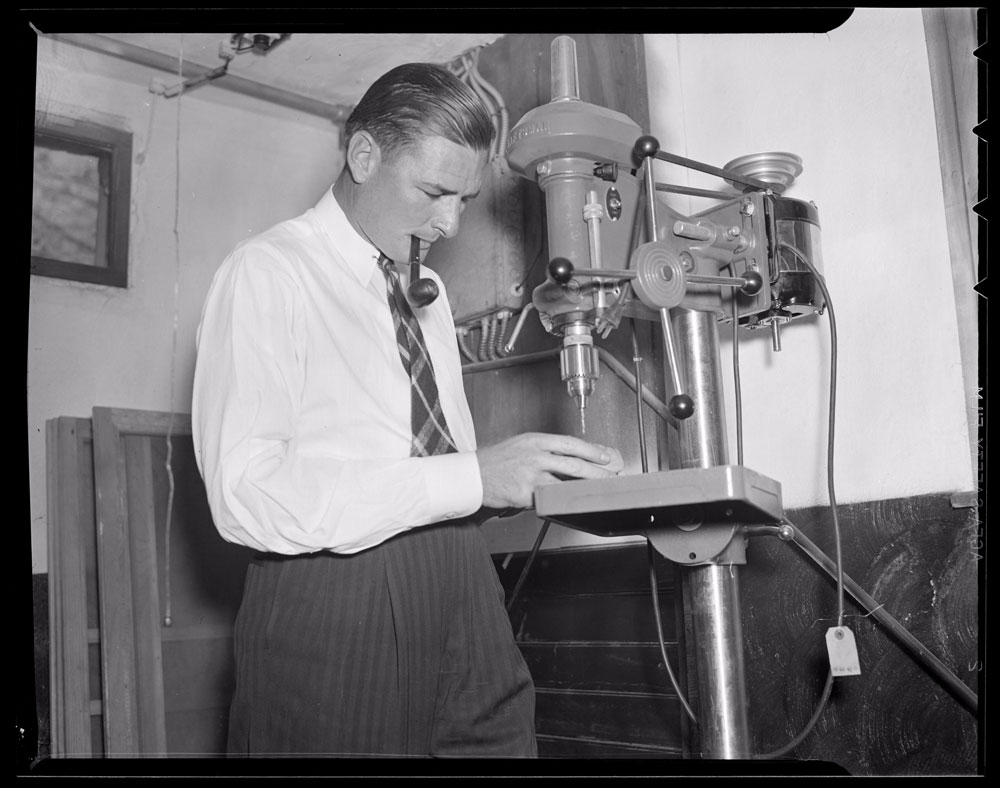

Perhaps, however, I had better make my position quite clear. I have no desire to see the home workshop completely mechanised, but I believe that there are advantages in the use of certain machines without any corresponding drawbacks, providing you use them for their legitimate purpose. In no circumstances would I alter either the design or construction of a job merely to enable a machine to be used. But where a machine would do a job equally as well as handwork (or possibly better) I would not hesitate to use it.

After all, remember that every woodworker does this to an extent in any case – unless he buys a tree, cuts it up himself, and waits a few years for it to season, etc. If he is purist enough to buy his wood unplaned he has at least allowed the machine to cut it into boards for him. Now where is the difference in allowing the machine to saw up his boards and in cutting it to size on a small power saw? I for one never did care about the back-aching job of ripping out timber, and I fail to see how my work has lost anything since I invested in a small circular saw. I can in a way admire the purist spirit that prompts a man to rip out, say, some 2-inch oak, but I do not see what he has gained. Ripping out is an uninteresting job at best, and the machine does it equally well – possibly better.

I say, therefore, that a small circular saw is a justifiable and useful addition to the workshop in that it does just as well in a quarter the time a job which is donkey work in any case, leaving a man free to do other work which requires more skill and which is infinitely more interesting.