![IMG_4211[1]](https://i0.wp.com/blog.lostartpress.com/wp-content/uploads/2018/06/img_42111-e1530224366315.jpg?resize=640%2C854&ssl=1)

“Master Lowe’s picture sits above my desk. A daily reminder from circa 2000 when I was punk, lost, and running. I don’t know where I would be if it wasn’t for him. Each day I try to carry his knowledge and pass on the torch to the next generation. Sadly there isn’t many to pass the torch to. But I do bust my rump to make him proud.”

The post struck a chord with many. Some shared their own appreciation of Phil, and also of Freddy, not least for being the kind of guy who takes the time to honor his mentor in public. As the comments went on, it became clear that many were responding more to the lament than the appreciation – some focusing on what they see as a lack of the requisite work ethic on the part of younger people, others on Freddy’s frustration with not having a worthy mentee, and a few on the dwindling number of mentors with the patience and generosity of spirit it takes to teach less experienced people on the job.

I added an observation based on my own experience: “I have to disagree. There are people aplenty waiting to take hold of that torch. The bigger question concerns the market, i.e. the ‘demand’ for the obviously super-abundant supply of skill and willing work.” Along with some other commenters, I was referring to the torch of doing the work, not teaching others how to do it; in other words, what I understood by the “bust[ing] my rump to make him proud” part of Freddy’s post.

I kept up with the comments all evening because this is a subject that interests me and I admire Freddy’s character, in addition to his work. Then I came across this one, copied and pasted here in its entirety:

“@nrhiller you’re crazy. It is common knowledge that less and less youthful people are willing to go into trades, put in the hard work, and stay off of their phone apps for more than 45mins at a time. Maybe geographically you have some different characters however this topic is discussed often in trade mags and even dudes like Mike Rowe.”

This one got to me. Not because the writer called me crazy — nothing new there. Nor was it the comment’s apparently unintended self-contradiction — “less and less youthful people” strictly means people who are growing older* (i.e., all of us). What bugged me was the generalization about “youthful people,” because I know a number of youthful people who possess an admirable work ethic and understand that nothing worth doing can be mastered without serious effort.

*I think what the writer meant was “fewer and fewer.”

+++

In any discussion that even implicitly invokes some supposedly better time, as many of the comments on Freddy’s post did, it’s important to distinguish between history and fantasy. I doubt that there has ever been a Golden Age when youthful people universally grasped the importance of what we geezers call paying our dues. “The younger generation” has a long history of taking knocks from elders.

What IS different today is how our culture legally and institutionally conceives of childhood and child-rearing, not to mention risk and investment, authority and discipline, work and leisure. Ours is a culture with exceedingly low expectations – a culture that heaps praise on those who do little more than show up. It’s one that rewards us for fulfilling the most basic responsibilities of citizenship with flag-draped stickers announcing “I voted” and tells university alumni they are “awesome” for taking the time to weigh in on their alma mater’s trustees. One that increasingly molds education on an entertainment model, treating students as customers in an economic transaction instead of encouraging them to embrace the existential challenges that are integral to anything worth calling education. Ours is a culture that

glamorizes consumption and goofing off and creates special incentives to attract “clean” tech jobs to century-old factories, then brands those sites a “Trades District” – because we all know the trades are cool, even if the actual work they involve is not-clean, not to mention no longer economically viable.

+++

As the comment about my insanity marinated, it occurred to me that I happened to have a youthful person right outside of my shop. He was working with gusto in the heat of a south-central Indiana June afternoon. Asher McDaniel is 12 and has been actively working since the age of 7. His jobs at home include feeding the dog, sweeping the barn, and tilling the garden – it’s 5/8 of an acre, on which the family grows the majority of its vegetables each year. This level of responsibility is not inconsequential.

![IMG_4212[1]](https://i0.wp.com/blog.lostartpress.com/wp-content/uploads/2018/06/img_42121.jpg?resize=640%2C853&ssl=1)

Asher continues to maintain those mowers, in addition to the one owned by his older brother, who operates a mowing business.

Asher’s thoughts on work?

“I like it,” he says. “It pays pretty good.” How much does it pay? “Eight dollars an hour. That’s 75 cents more than what I could make flipping burgers.” (Not that he would be flipping burgers at his age. There’s a legal difference between minors working with their parents and those who are employed by others.) But the pay is far from the only motivation. He’s homeschooled. This work is no less integral to his education than his state-mandated academic studies and lessons in guitar.

Asher has been going to work, on and off, with his father for five years. This is in addition to what he does around the family farm. “I like going to work with him,” he says. “And I like the kind of work it is.” Liberate yourself from prevailing norms and you may glean just how rewarding vigorous physical work and the kind of constant problem-solving Matthew Crawford wrote about in “Shop Class as Soulcraft” can be. You may appreciate the sense of competence that comes from making an undeniable difference in the world around you.

“I didn’t have a lot of the same opportunities at his age,” says Aaron, in a statement some may imagine was intended to be ironic. (It was not.) When Aaron was 14, Aaron’s father left his job in research and development for a corporation to start a family farm. “I saw (my father’s) work ethic and admired it,” Aaron says.

As a result, Aaron and his wife, MeChelle, who shares his perspective on the value of labor and family, decided to include their children in their own work from a much younger age – not because doing so was convenient, but, as Aaron puts it, “because I wanted to share my joy and satisfaction with them.”

If your reaction to this statement is one of cynical disbelief – because how many of us today see hand-digging a trench through gravel on a humid summer’s day as a source of joy and satisfaction? – you may be contributing to Freddy’s problem. This is not just about young people.

“One of the measures of success is how far we can distance ourselves from physical and mental strain,” Aaron adds. “If we value work – if our attitude to work is that it’s profitable and good and healthy – we’ll want our children to participate with us.”

+++

Finally, back to that comment. I asked myself, “Who the *&^ is Mike Rowe and why should I care about what he has to say on this matter?” (We don’t have cable TV.) Before writing this post I looked him up online and found this presentation, which speaks volumes more about this subject than I can convey.

So, thanks, commenter, for turning me on to a onetime scholar of Classical Greek who is getting people to question attitudes about work. If more of us consider the bigger picture and our own part in it instead of just complaining that young people are lazy or “entitled,” we may have a shot at making things better.

— Nancy Hiller, author of “Making Things Work“

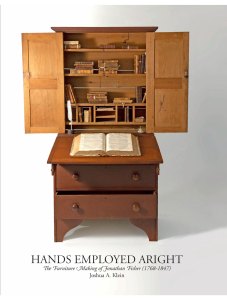

You can now place a pre-publication order for Joshua Klein’s “

You can now place a pre-publication order for Joshua Klein’s “