Tom Bonamici is the designer behind most of our soft goods (plane and pencil pockets, workshop waist aprons, bandanas, chore coats, vests and more). He’s also a woodworker and educator who has climbed volcanoes, attended New York Fashion Week, built privies and is likely on a backcountry motorcycle trip as I write this.

Tom grew up in Eugene, Oregon. He spent his childhood outdoors knocking around Eugene’s urban forest areas wearing moccasins he made after immersing himself in books on Indigenous American material culture, fly fishing with his dad and cruising around town on his bike with friends. He has an older sister, now a journalist in Boston. His mom dipped in and out of various jobs including full- and part-time caregiving, and working at a marketing firm, an organic food store and University of Oregon’s (UO) Clark Honors College. He remembers watching his dad, an academic librarian who spent his entire career at UO’s Knight Library, tying his own fishing flies and making knives.

The closest public school just happened to be a French immersion school. Learning another language served as a good brain teaser growing up, and now helps him navigate Europe, “in my very enthusiastic French, which may or may not be correct,” he says, laughing.

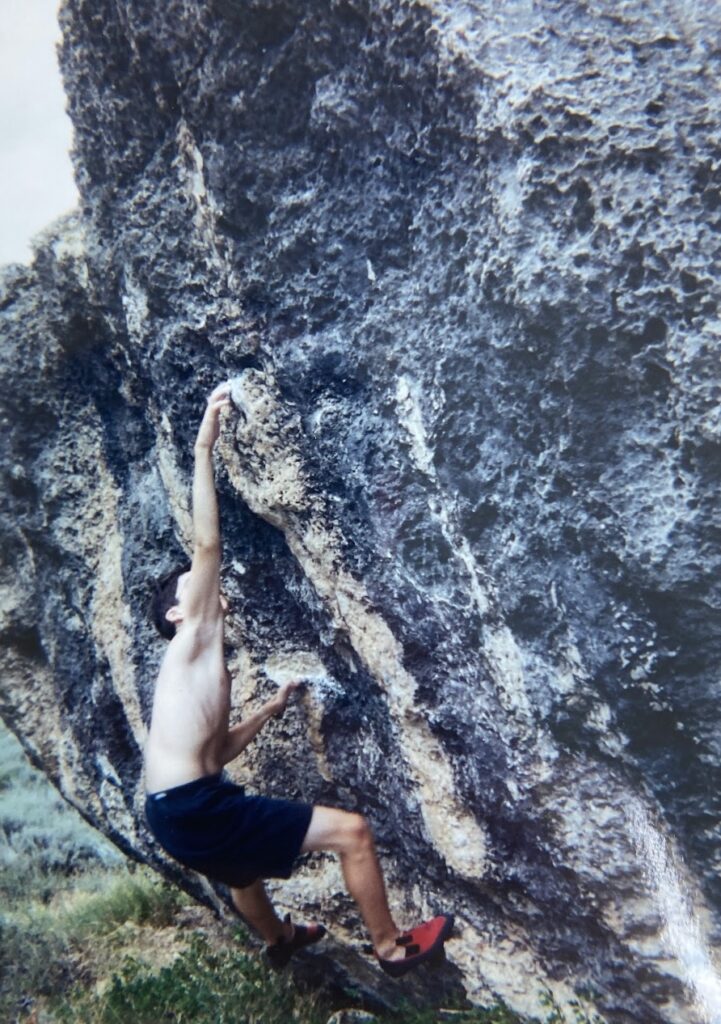

When Tom was about 8 years old his mom took him to REI. A rock climbing gym across the street had set up a little climbing wall in the store. Tom tried it out.

“And I just got obsessed with rock climbing,” he says. “Until maybe 15 or so, that was my life.”

It was the very early days of the Junior Competitive Climbing Association (Tom was member No. 12). He climbed in competitions all over the West Coast, and even went to nationals a few years.

In 8th grade, Tom got into a bad bike crash. With forced time off from climbing competitions he realized how much more fun it was to simply climb outside with friends. He left the pressure of competitions behind and moved on to alpine climbing and backpacking. He helped start a mountaineering club at his high school. And he did several big climbs – Mount Hood, Mount Shasta and smaller volcanoes in Oregon. He also took some big backpacking trips, including a month-long NOLS course in Wyoming when he was 17.

Tom looks back with a bit of awe at how trusting his parents were, allowing him to head off with friends and adult climbing mentors to climb mountains, take a 12-hour trip to Spokane for a competition or spend the weekend backpacking.

“It was pretty wonderful,” he says. “It showed a lot of trust. I had some really wonderful mentors and learned a lot.”

Dartmouth’s Outing Club & an Education In Timber Framing, Geography & Studio Art

Tom attended Dartmouth College, in Hanover, New Hampshire, where he was given the freedom to create his own major – part geography, part architectural history, part architectural justice, part studio art. He likes to call it “cities and buildings.” Tom focused on human geography, looking at how the built environment affects people, privileging some and criminalizing others. He took lots of architecture studios. Timber framing and the buildings in New England, so different from where he grew up, inspired him. When Tom asked to forge his own path, the deans at Dartmouth simply asked for a proposal.

“That trust of students still inspires me in my work,” Tom says.

To further illustrate this trust, Tom shares a story. In middle school, he took a class at a cycling center and got really into fixing up old bikes. At Dartmouth, he noticed abandoned bikes locked up on bike racks for months on end. After about a year, he decided to liberate them. His intent? Fix them up for friends. While liberating one such bike a campus police officer showed up. Tom explained.

“Yeah, I can tell that it’s abandoned but you can’t just take it,” the officer said.

Long story short, Tom ended up in a room with one of the deans. He braced himself for consequence but was instead met with curiosity. The dean asked him to put together a proposal for a program for abandoned bikes, and Tom did. It included a budget, storage solutions and how they would be distributed via the college’s cycling club. Tom says the abandonment of hard-and-fast rules for trust, responsibility and accountability in that moment was eye-opening.

Tom largely chose the college due to the Dartmouth Outing Club, “which is this wonderful storied institution that started in 1909,” he says. It’s student driven, and nearly a quarter of the college’s students are members. In addition to networks of trails, shelters and cabins, the Outing Club offers nearly every outdoor program you can think of, from water sports, skiing, hiking and climbing to hunting, fishing and forestry.

“It’s just an amazing organization and a real education because, again, the amount of trust and responsibility the adults gave the students was such a gift,” Tom says. “We were put in charge of pretty significant projects.”

An example: The summer after Tom’s freshman year, he and two fellow undergrads were responsible for rebuilding a long stretch of the Appalachian Trail that ran along the side of a mountain in New Hampshire. Dartmouth provided them with a course called “Wilderness Chainsaw Use,” taught by the U.S. Forest Service, then simply gave them a truck, tools and list of work. That summer they replaced rock steps, rebuilt water bars and built a bridge.

“It was incredible,” Tom says. “I teach at a university now and that would never happen now. Never, ever. And it doesn’t happen at Dartmouth the same way. There’s much more supervision.”

Tom dedicated his time to the Outing Club’s Cabin and Trail division, which was responsible for maintaining almost 75 miles of Appalachian Trail (these days it’s less). Responsibilities included maintaining all the three-sided Adirondack shelters along the trail and their associated privies. During a meeting it was announced that the Cabin and Trail club’s Cabin Maintenance chair was studying abroad and they needed a replacement.

“For some reason I raised my hand not knowing anything,” Tom says. “And I got handed my first assignment, which was to replace two outhouses.”

As luck would have it, a man named Ira Friedrichs showed up at this same meeting. Ira wasn’t a student. An apprentice to Jay White Cloud, a master timber framer in Thetford Hill, Vermont, Ira was simply hoping to meet some people and maybe help out with a few projects. He and Tom hit it off, and Ira suggested they timber frame the privies together. Ira taught Tom Japanese timber framing and over spring break they pre-cut two small timber frames for the privies. Appalachian Trail regulations required the outhouses be wheelchair accessible, which meant each structure needed a 4′-wide circle. Despite using 2x4s and 4x4s, the frames were heavy. One of the privies was to be located a couple of miles in on a flat trail. Tom and Ira lashed the timbers to wheelbarrows and carts, hand carried them, and put them up in a weekend, hanging the walls on French cleats. The second outhouse, however, was on top of a mountain.

“And that was pretty brutal because we had to slog through mud and this dude was trying to help us with an ATV but that kept getting stuck,” Tom says. “So we’re skidding these timbers up and it was a disaster. But we got them up there eventually and we kind of bodged it together and it was fine.”

Tom fell in love with timber framing. He and Ira timber framed the Appalachian Trail’s Velvet Rocks Shelter, and the summer after he graduated, Tom designed and timber framed a sugaring house for an organic farm. He felled the trees, worked with a local sawyer to mill them and erected it on site.

“That was just a really neat farm-to-table building experience,” Tom says.

An Open Woodshop

While at Dartmouth, Tom also had access to the Student Woodshop, located in Dartmouth’s Hopkins Center for the Arts.

“It started in the ’20s and the story I heard was some alumnus said, ‘The men of Dartmouth are getting weak and not learning how to use their hands. I’m going to endow a woodshop so that they can remember what it is to be real men!’ You know, some bullshit like that. But the institution has definitely lasted and it’s just wonderful. It’s an enormous woodshop with wonderful tools and a full-time staff.”

There are no woodworking classes, rather the Student Woodshop is simply an open studio. Tom wanted to build a blanket chest so he checked it out. Staff including Greg Elder, director of the Student Woodshop, taught him how to use the tools, how to think about what’s needed to take rough lumber to square, and how to balance hand work with machine work.

“It was just an amazing privilege to have access to that and that just gave me such a bug,” Tom says.

Occasionally, Walker Weed, former director of the Student Woodshop, would come by to use a machine. Reed was a well-known New England studio woodworker who had been featured in Fine Woodworking, “a good legend and guiding light at that place,” Tom says.

Throughout college Tom made a bunch of little blanket and sea chests – a lot of machine dovetails, he says. After graduating in 2007, he sharpened tools at the Student Woodshop a few hours a week, giving him full access to the shop. Then, he started getting commissions. First was the sugaring house for the organic farm. Then Jay hired him to help build a small wing onto his house. And a local guy asked him to build a fly-tying desk.

“I just bit off way more than I could chew,” Tom says. “I made this really elaborate crazy-ass thing. The whole base was basically timber framed with all these big wedged through-tenons. And then the top was all hand-cut dovetails on this stepped, Tansu-looking series of little cabinets, all hand-cut dovetail drawers, and I think I asked for what at the time felt like an impossible price and then of course I ended up making about $3 an hour.”

During his senior year, Tom learned about a grant from Dartmouth’s art department: An alum had given money so that students could go to Europe and be inspired by architecture. That sounded pretty good to Tom so he applied and got the grant. After graduation he stuck around Hanover for about 10 months then bummed around Europe for three months, stretching the grant as long as he could.

Archival Clothing

Once back from Europe, Tom returned home to Eugene, where he lived for a few years part-time. He took occasional jobs at Dartmouth and traveled, and when in Eugene he worked as a prep cook in a French restaurant, later moving to the restaurant’s coffee shop where he slung espresso for a while. Around this time he reconnected with an old friend, Lesli Larson.

“She was a very influential person,” Tom says. “She loves old clothing, fishing and outdoor clothes, and she had this great blog called Archival Clothing. And we are just really good buds. We’d go on long-distance bike rides and chitchat about all the old clothing and ephemera that she had.”

Eventually, Tom and Lesli decided to make some things inspired by Lesli’s collection and sell it on Lesli’s blog. They found a sewing contractor in the Yellow Pages – T & J Custom Sewing & Design. The owners, Julie and Terry Shuck, turned out to be “amazing folks,” Tom says, and coached them through the conception-to-reality process.

First up was a bag. The Shucks asked for a drawing and material, and explained how the pricing would work. Using what he learned about technical drawing in his architecture studios, Tom drew up some pencil fashion plates and sewed some crude prototypes. With that, the Shucks made 20 bags, and Tom and Lesli put them up on Lesli’s blog. They immediately got snapped up.

“We thought, That’s really fun,” Tom says. “And then we just kept doing that. We did a bigger run of bags and a bigger run of bigger bags and we made backpacks and before you knew it we had a third business partner, one of Lesli’s college friends. And we had a full-on company on our hands called Archival Clothing.”

Tom began to look more closely at product design as a career. He applied and was accepted into the Pratt Institute in Brooklyn, New York, to earn a master’s of industrial design degree. His thesis was on the physical infrastructure of home cooking but his real education, he says, had more to do with the success of Archival Clothing.

“It was really good timing,” Tom says. “I moved in summer 2010, the peak fever of the men’s heritage trend. Everyone wanted Filson stuff and Barbour stuff and wax cotton this and heavy wool that and that has always been Lesli’s thing.”

Living in Brooklyn, Tom was able to go to New York Fashion Week events and meet with stylists. Archival Clothing did a co-op with Barneys New York. The company was mentioned in The New York Times. Tom met Archival Clothing’s Japanese, Scandinavian and other European distributors. He went to shows in Berlin.

“It was a really incredible education and I think I might have learned more doing the Archival Clothing stuff than in grad school just because it was so applied and so immediate,” Tom says. “It was just a phenomenal, and sometimes difficult, education in product design, production and sales.”

Tom says if he had his wits about him he would have been a little more consistent, studying domestic manufacturing of soft goods, for example, versus industrial design.

“One of my many foibles is over-enthusiasm that spreads me a little thin,” he says.

From Office to Classroom

Tom and Lesli are still best friends, but after some disagreements with their third business partner, Tom left Archival Clothing. In 2014 he got a job as design director at Best Made Co., where he was immediately thrown into the deep end, being tasked with designing everything from men’s shirting, outerwear and bottoms to steel storage solutions.

“The founder might have an idea for something and then with relatively limited marching orders I was responsible for making it happen,” he says.

He also learned some valuable lessons.

“I definitely had my share of fails where I just overpromised what I thought could happen and I had to learn a lot about being realistic in industry production and maybe not trusting everything that everyone says all the time,” he says. “I’m a very trusting person by nature and that definitely bit me in the ass a couple of times. But it was a great education, some super nice folks and I learned so much.”

About a year in, Tom was feeling burnt out. He was spending 50 to 60 hours a week in the office, in front of a computer. He missed making. So in 2015 he quit and teamed up with a friend, Anthony Zollo, to build custom furniture in New York, France and Sweden. Then, after six years in New York, he moved back to Oregon.

“I was ready to be somewhere with some trees,” he says. “Somewhere I could have a car and get out to the sticks a little bit better.”

Tom was building fences and decks while contemplating his next move when an Archival Clothing contact who worked at UO reached out and said that one of their product design adjuncts had just bailed. They wondered if Tom would be interested in teaching a studio in the upcoming term.

“One thing led to another and in no time flat I was teaching full time,” Tom says. “It was just an immediate fit. It just felt right.”

Teaching Studios, Building, Research & More

Teaching wasn’t entirely new to Tom, who had taught a number of timber frameing workshops in upstate New York, Oregon and California. After teaching just one studio at UO, he remembered how much he loved it.

“The students were so inspiring and awesome and the conversations were exciting and challenging – it was just an immediate good feeling.”

And while he always has side projects, Tom has been a career instructor ever since. In some of his classes in UO’s Product Design department, Tom introduced students to woodshop tools, teaching them how to use jointers, planers and table saws, and how to think critically about the tools and materials so they can design accordingly. The goal of these classes is not to crank out expert woodworkers but to teach process and materials, resulting in future designers who are more comfortable navigating different aspects of their career. Tom also taught students how to use industrial sewing machines, how fabric works and how to design bags and garments. Students would sew pouches, cases and totes, learning how to work though different seam constructions and how different materials function in different applications. In advanced studios, students tackled a single subject for the entire 10-week term.

“Last term I taught an advanced studio and I had students design headlamps,” he says. “And it was a great one because there are so many tiny details to attend to.”

The studio starts broad, with concept design and Tom asking questions: Why make this? There’s a lot of stuff in the landfills, do we really need this? Where does this fit in? He taught the students how to think critically about intuitive functioning, how to easily communicate multiple settings and how to make special considerations for niche users, such as runners. Students explored their concepts via sketches, models and technical drawings that become more refined with time.

Because of Tom’s professional background in soft goods, he frequently taught garment and bag design studios. Frustrated with the plastic Janome sewing machines in UO’s sewing studio, Tom helped build out a more legit lab with industrial machines.

This year a tenure-track position at UO’s satellite campus in Portland opened up, and Tom applied and was hired. The campus is home to fourth-year undergrads as well as two-year master’s students studying sports product design. Tom’s focus will be on soft goods, such as garments, shoes and bags.

“I’m really excited about it,” he says. “It’s going to be a big shift. I’ve been dating my partner, Karen, for two years now and we’ve been long distance. She lives in Portland. So I’m very excited to be finally moving in with her. And I’ve got a ton of friends in Portland because I’ve spent a lot of time up there. I’m very comfortable in the city so I know what I’m getting into. It doesn’t feel as scary as a move might be otherwise.”

When applying, Tom put a lot of thought into his proposal for his research project and how it might relate to the UO’s institutional hiring plan, which was focused on health and human performance, as well as environmental responsibility.

“I was applying to this program in sports product design but I wanted to come at my research at a really genuine angle,” Tom says. “I couldn’t say I wanted to design football cleats because that’s not my thing, it’s not my world. I would love to work with a student who is designing football cleats and I think I could do that very well, but myself?”

A love of outdoors has been the straight stitch in Tom’s life, something everything else has stemmed from, sometimes in surprising ways. Tom rooted his research proposal in ultra lightweight backcountry travel design concepts that could translate to other situations, such as wildland firefighting.

“That’s such a high-risk, high-demand, super-necessary job and those firefighters carry so much stuff,” he says. “Even if we could reduce that pack weight by just 10 to 15 percent, that would make a huge difference toward their health and human performance. But it’s all pretty new. I’m starting in the fall and we’ll see how the research goes.”

Designing for Lost Art Press

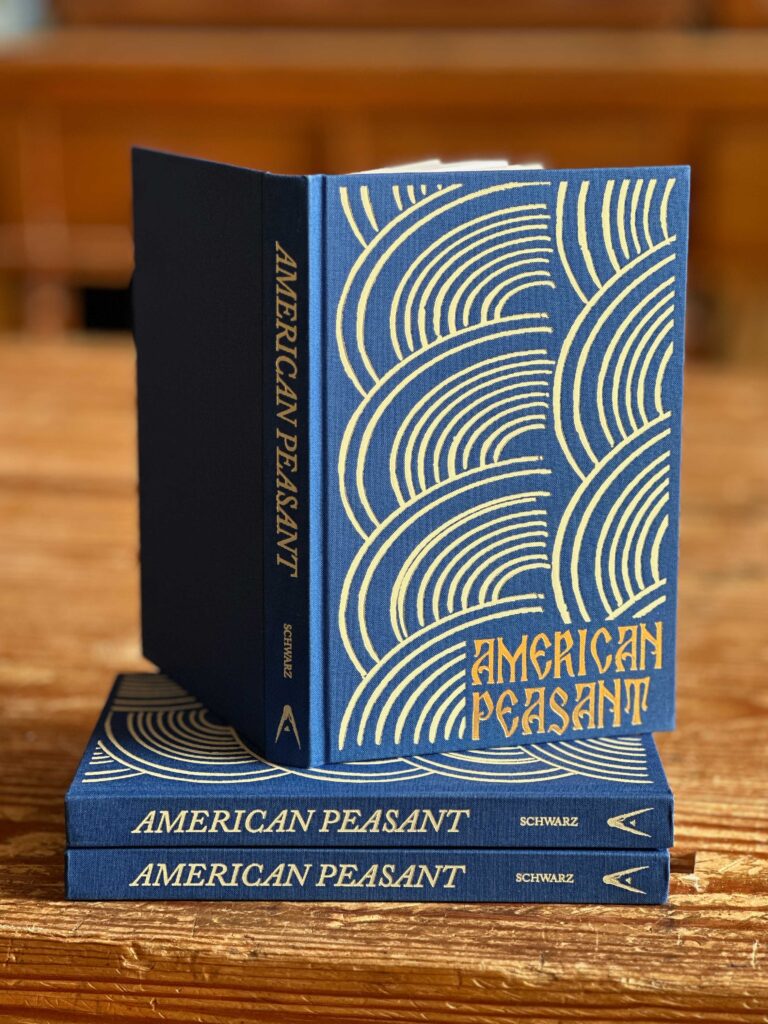

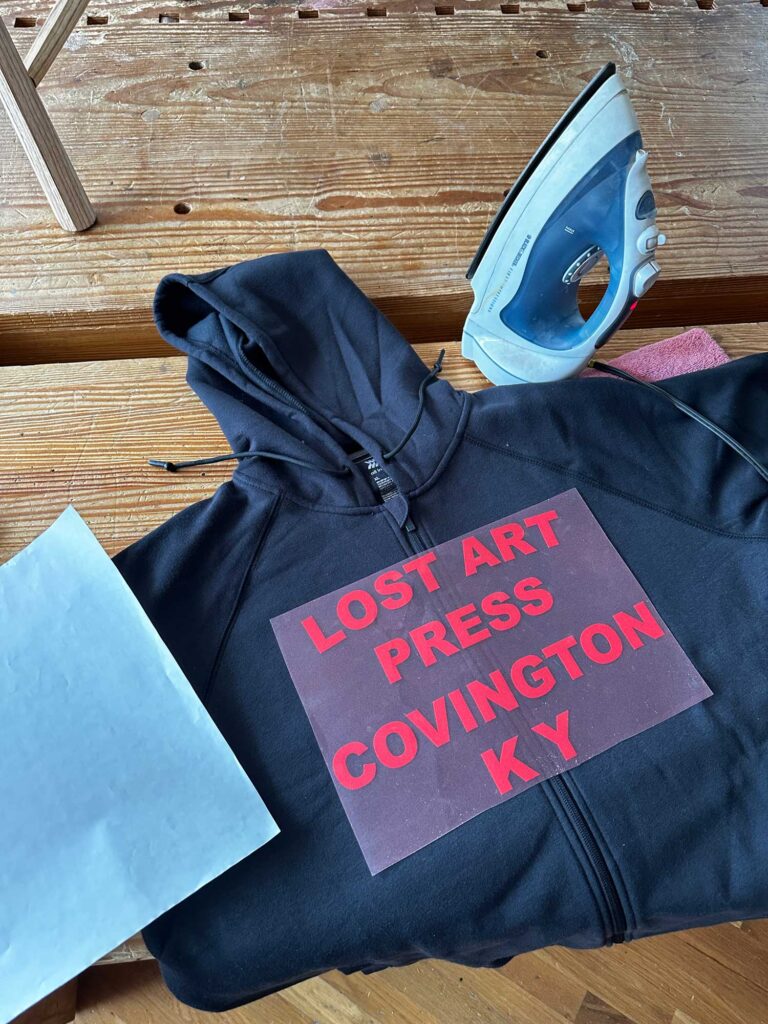

Tom had been following Christopher Schwarz and Megan Fitzpatrick’s work from afar as an enthusiastic woodworking for quite some time. While working at Best Made Co., Tom cold emailed Lost Art Press and said they were interested in selling Lost Art Press books online and in Best Made Co. stores, perhaps reaching a slightly different audience. The books sold well, particularly Christian Becksvoort’s “With the Grain.”

In 2015, while driving across country in his move from New York City to Oregon, Tom stopped in Indiana and took a class with Chris at Marc Adams School of Woodworking. That was their first time meeting in person. They got along well.

“We both like to bullshit and drink beer,” Tom says.

Tom noticed that Chris was wearing this great French chore coat. He told Chris to hit him up if he ever wanted to make chore coats.

“And that was it,” Tom says. “I’m not good at selling, being pushy with my services. I think that’s all I said. And maybe a year later he hit me up and was like, ‘Hey, let’s make a chore coat.’”

Together they produced a limited run of chore coats at a factory in Oregon. It’s still the favorite item Tom has designed for Lost Art Press.

“They were so nice,” Tom says. “That was the first round where we used this really, really fancy and horrifically expensive Japanese reverse sateen moleskin, which is this really lovely fabric. And the factory did the run and then they changed the pricing on us. Producing clothing is always very challenging. But the sales were great and we produced well over a thousand coats for Lost Art Press.”

These days he and Chris have focused more on workshop accessories, in part because workshop accessories don’t come in different sizes.

“I think it was a surprise for the Lost Art Press folks to see that 5 to 6 percent of the clothes just come right back,” Tom says. “I was like, ‘Yeah, guys. Sizes. Busts and arms and shoulders. It ain’t like a book.’”

Sew Valley in Cincinnati makes the plane and pencil pockets. Tom worked with Megan and Chris to not only make sure each pouch would function properly but that it could also be produced within Sew Valley’s capabilities.

“That’s such a big part of designing, just understanding what machines your suppliers have and therefore what kind of operations they can do with those machines,” Tom says.

Tom also enjoys designing bandanas for Lost Art Press.

“I love doing the hankies just because it’s a different prompt every time,” he says. “Chris and I will generally chat a little bit on the phone and then I get to doodle around and it’s just a fun way to get lost in some illustration and do something that just feels a little free. And the vendor we work with does a beautiful job. One Feather Press makes really nice work, really great printing and high-quality material. They just do a really nice job.”

Tom says the profit sharing Lost Art Press does with its authors and designers is unheard of.

“It’s so easy to work with Chris and Megan because they trust me and that is rare as a freelance designer, to be trusted,” he says. “And they are always down to try something and if it doesn’t work they’re like, ‘Cool. We tried it.’ No one is ever upset when we don’t achieve maximum profitability on something. It’s just a really special organization to work with. Chris walks his values in a way that I’ve almost never seen before. And don’t tell him I said that because he can’t take a compliment. It’s insane. It’s remarkable.”

A Shift

Tom is spending this summer getting his house in Eugene ready to rent and going on a couple of backcountry motorcycling trips in Oregon.

“There’s just so much public land, mountains and desert and forest here in Oregon that it’s just a great way to get around and see some cool country,” he says.

He also has a couple backpacking trips planned, and a trip to Ireland with his family to celebrate his mom’s birthday, who is from an Irish family but has never been. Karen, his partner, is really into fishing, so there will be a lot of that as well. And then Tom will move to Portland. Work starts in August, as he helps facilitate a campus move.

“It’s going to be a big year of change and I think it’s going to be really positive,” Tom says.

— Kara Gebhart Uhl