This week I’ve thrown myself into production for Crucible Tool along with help from Megan Fitzpatrick and Brendan Gaffney. Today, Megan and I finished up 600 card scrapers and sent them to the warehouse. They should be for sale by the end of the week – so take this as fair warning.

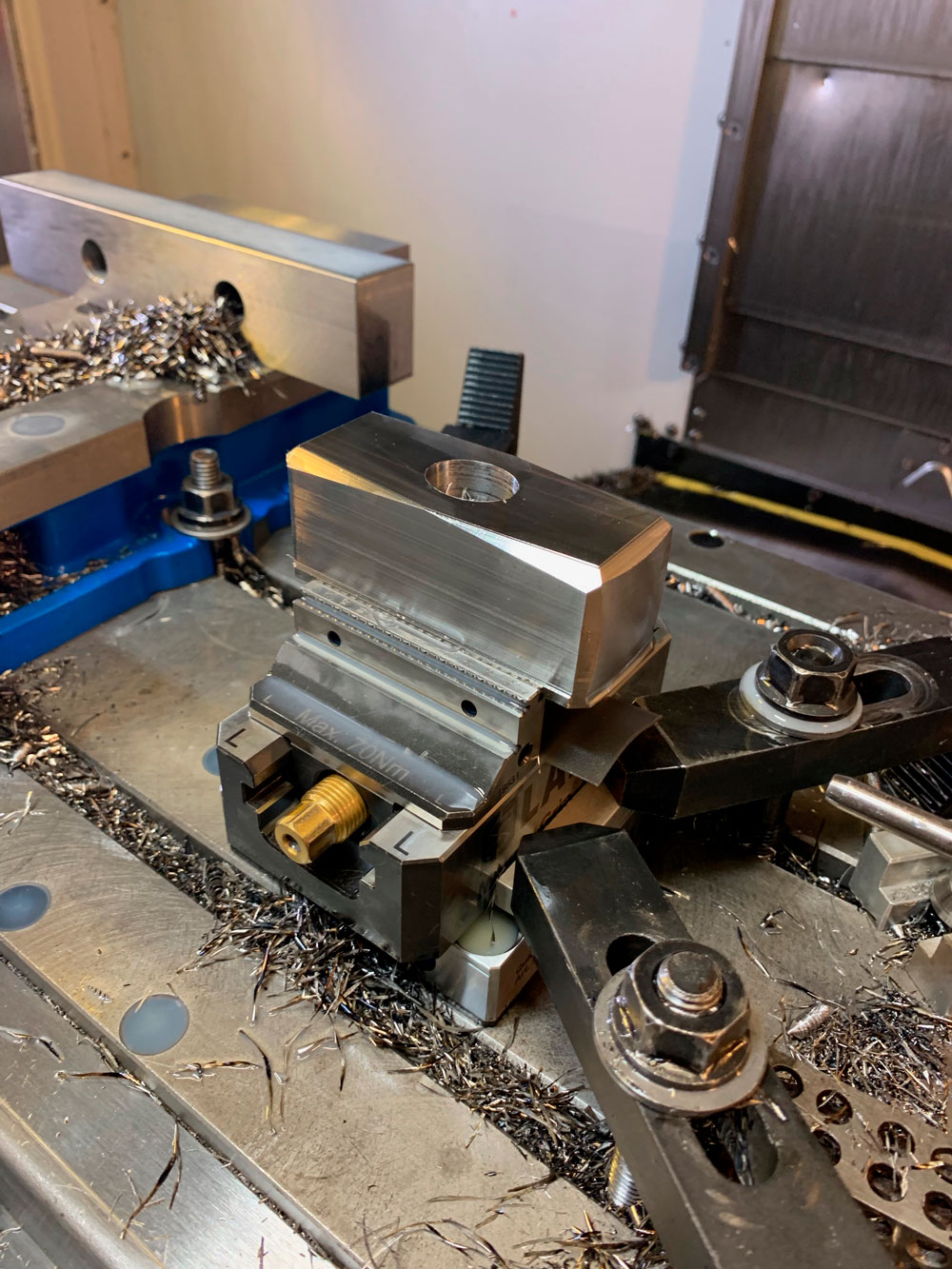

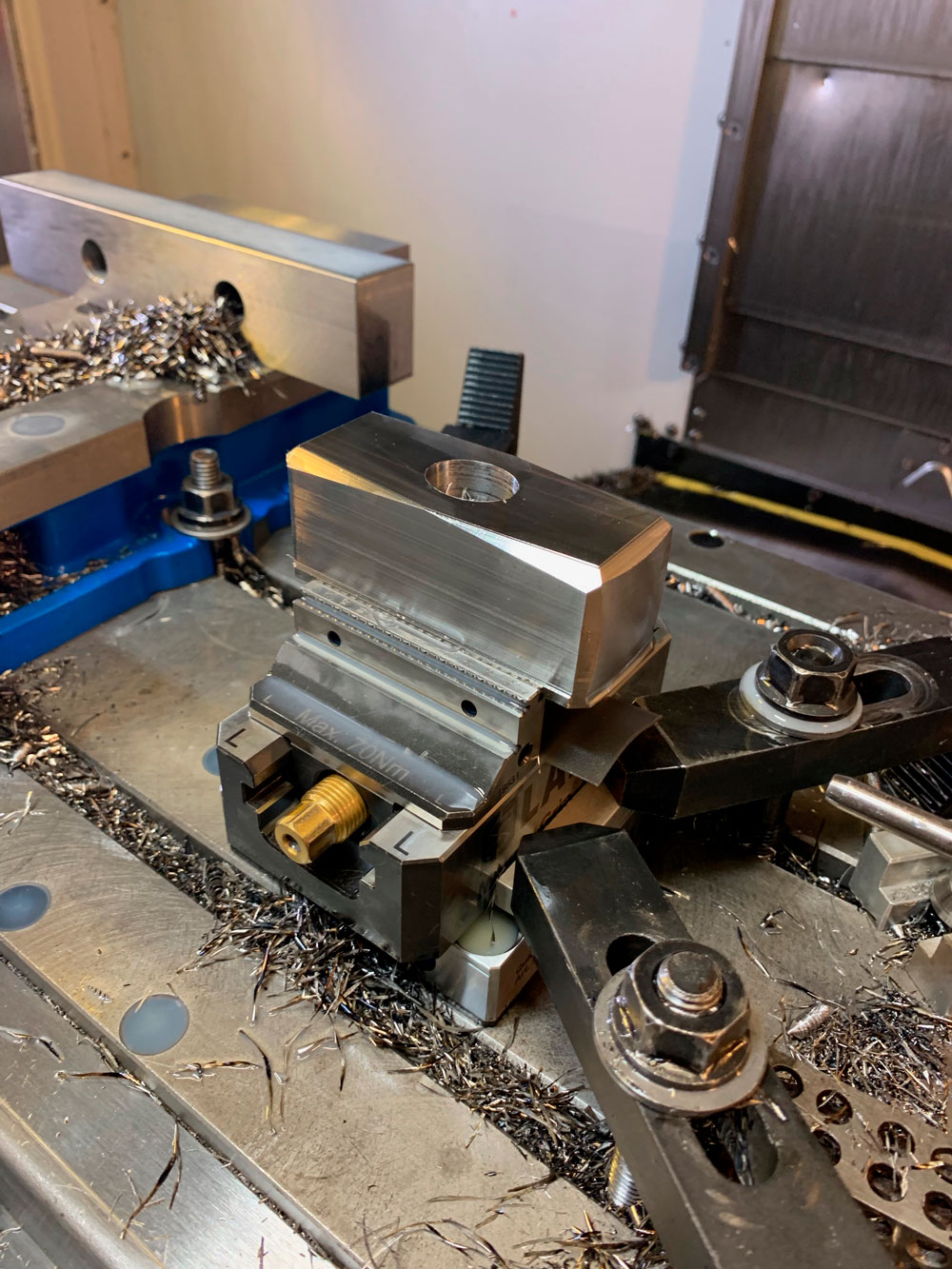

We have a new jig for machining the scrapers in a CNC mill. This speeds the process and eliminates the abrasive polishing of the edges. That’s a win for everyone’s lungs (and fire suppression equipment). Abrading metal blows. And burns.

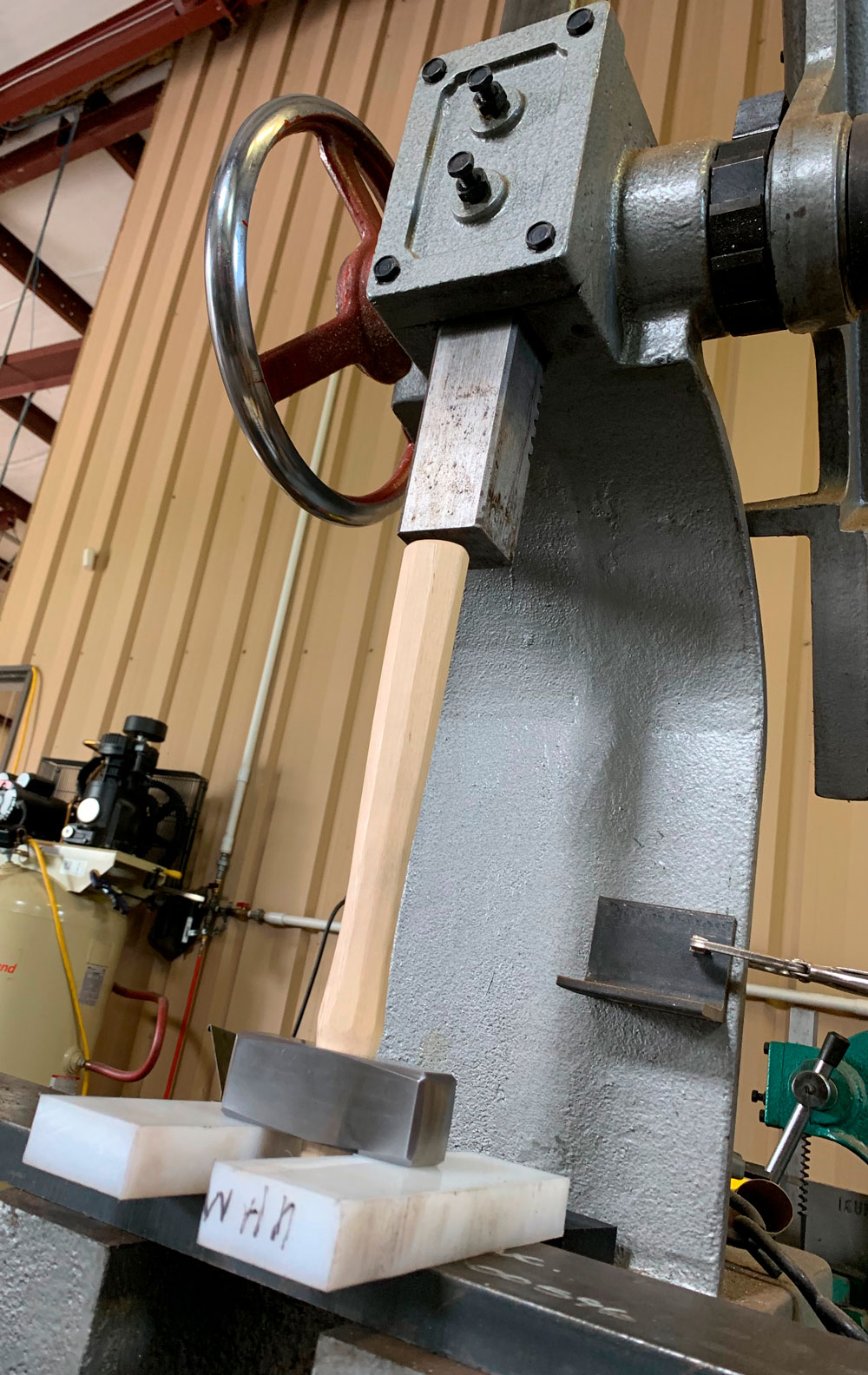

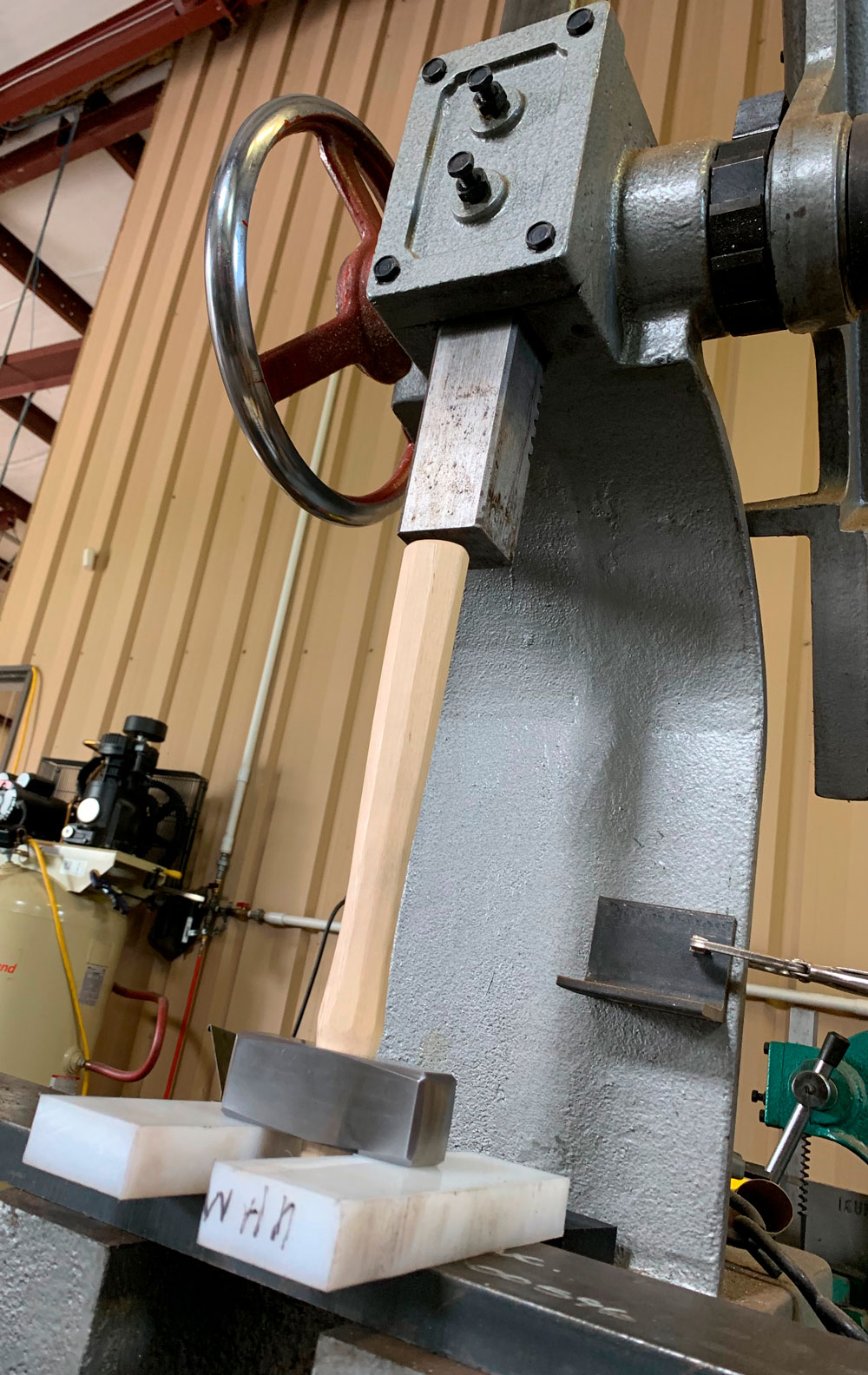

Speaking of abrasives, during the last month, we’ve redesigned the way we make hammer heads to reduce – and almost eliminate – the abrasive grinding processes to make the heads for our lump hammers.

I know that some of you simply want your hammers and don’t care about how they’re made. If that’s you, know that we should have a batch of hammers for sale next week. You can now go back to your cat videos.

For those interested in how your tools are made, here’s what we’ve been up to. When we started making the hammers we machined the heads and then had five abrasive processes to finish them. We used three grits on the flat faces and two on the striking faces.

With the magic of changing the tool paths, we’re down to one abrasive process. We’re hoping to eliminate that one as well and just have a little power buffing.

The heads won’t look different to the naked eye. All the facets are the same. The striking faces are the same dome shape. But the surfaces look a wee bit different under a loupe. I think they look better.

Note: After five minutes of hard use, all our hammers look about the same.

All these changes will make the heads easier to make. And it’s safer for the machine operators. So thanks for your patience (like you had a choice).

— Christopher Schwarz

P.S. Before you email John and Meghan: No, we’re not working on dividers. That tool has been suspended until it can be redesigned.

Like this:

Like Loading...