A reminder that at 10 a.m. Eastern, registration opens for Covington Mechanical classes for the second half of 2025. See our ticketing site for more info (and to register at 10 a.m. Eastern).

— Fitz

A reminder that at 10 a.m. Eastern, registration opens for Covington Mechanical classes for the second half of 2025. See our ticketing site for more info (and to register at 10 a.m. Eastern).

— Fitz

Christopher Schwarz is the guest moderator for the next meeting of The Woodworker’s Book Club; at 6 p.m. Monday, March 2. The book under discussion is David Savage’s “The Intelligent Hand,” for which Chris was editor and publisher…and there endeth his suitability for the role.

Chris says, “I have never been to a book club and I don’t know what book clubs do or what you do during them, so I am completely qualified to be a moderator at the book club.”

So this ought to be fun!

– Fitz

Got a woodworking question? Post in the comments below between now and 5 p.m. Eastern, and we’ll do our best to answer. In between answering, Chris is getting ready for an upcoming class and video shoot with Jerome Bias, and I’m working on a personal project (so if we don’t answer right away, that’s why).

— Fitz

Comments have been closed. See you on April 19!

After a few years of drying, my workbench’s benchtop shrank a bit. It’s not a big deal, but the drying process also shrank my 1” holdfast holes. And with a few of the holes it became difficult to insert the holdfast’s shaft.

There are a few ways to open up the holes a bit. Reaming them out with a 1″ drill bit and “wallering a tad” works, but it can take some effort to get the middle section of the hole to size.

A second expensive-but-precise method is to use a tool called a “bridge reamer” or “car reamer.” These construction tools have a slight taper and are used to correct misaligned holes in steel construction and the like. These cost $100 or more, which is a lot for a single task.

The third option is to buy an inexpensive 1-1/16” drill bit such as this one. Before running this drill bit into your holes, I recommend you open up the top rim of the hole with a rasp so the bit won’t tear up your benchtop’s surface.

For drilling, use a corded drill with a side handle, especially if your benchtop is made of a hard wood. Yellow pine is especially tricky because of the differences in density between the earlywood and latewood. Take your time, don’t rush and you’ll get through it.

Holdfasts work best where there is a close fit between the shaft and the hole, so don’t over-do it.

— Christopher Schwarz

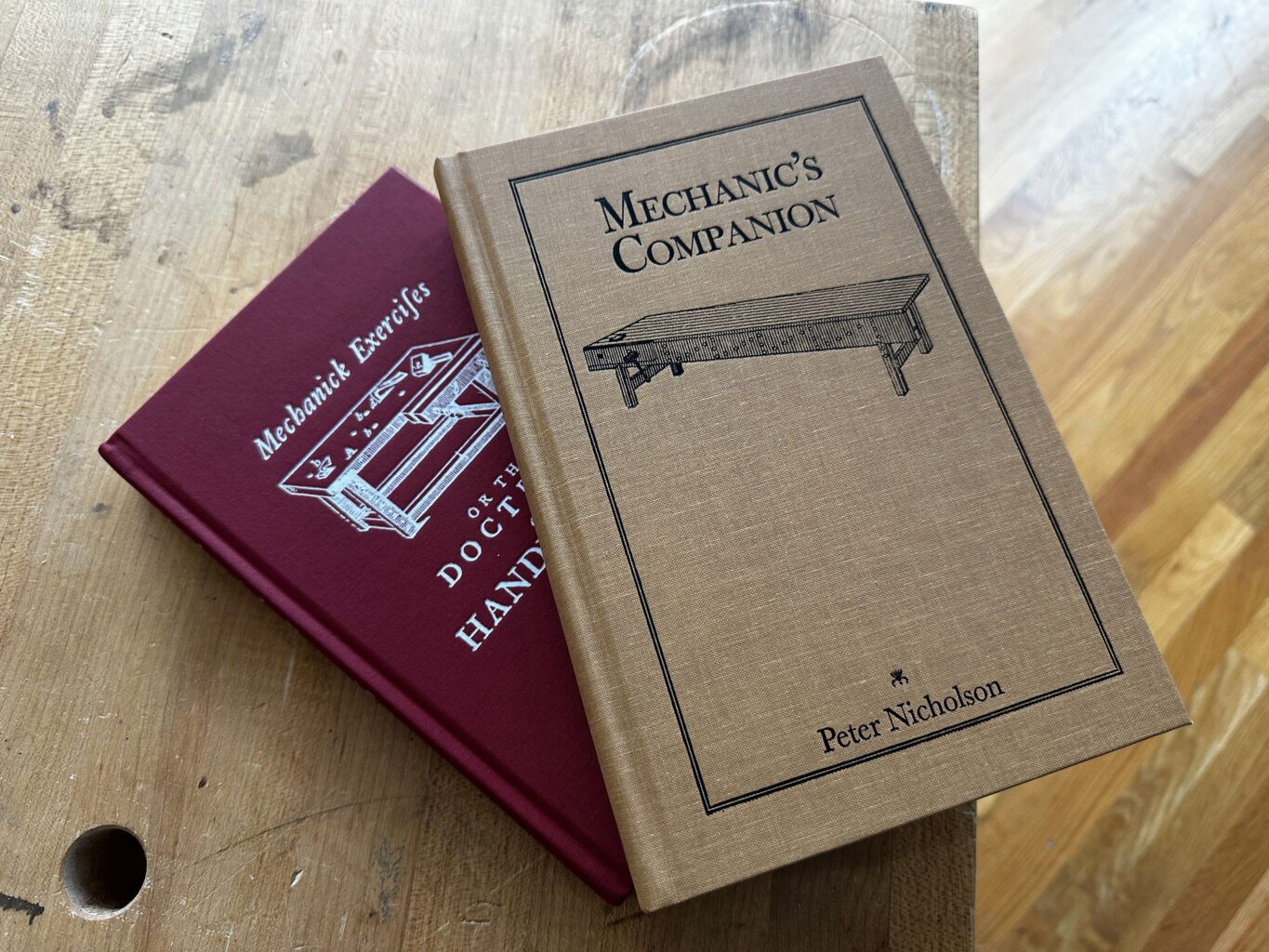

Here’s the news. We are closing out two of our historical reprints: Joseph Moxon’s “Mechanick Exercises” and Peter Nicholson’s “Mechanic’s Companion.” The books are now $13 each until we run out of stock. Act quickly to avoid disappointment.

I’m grumpy about this sale because I hoped to keep these two properly bound, nicely printed books in our backlist. But we don’t have enough space at our warehouse to do this. We are expecting about 12 pallets of new titles in the next two months, and I have no desire to (again) store books under my bed.

So this is your last chance to buy these two historical texts, which I consider the foundation of the craft in English-speaking countries.

These are well-made books: they are printed offset on a web press on heavy uncoated and natural paper. The signatures are sewn, glued and taped. Then the book block is fastened to the boards with a heavy paper hinge. All done here in the United States (Michigan, to be exact).

These books will last decades if not centuries.