Since returning home Saturday I have been pushing hard to get “By Hound & Eye” to the printer so we will have it out in time for Woodworking in America – yes, we are attending, and yes we will have a booth this year.

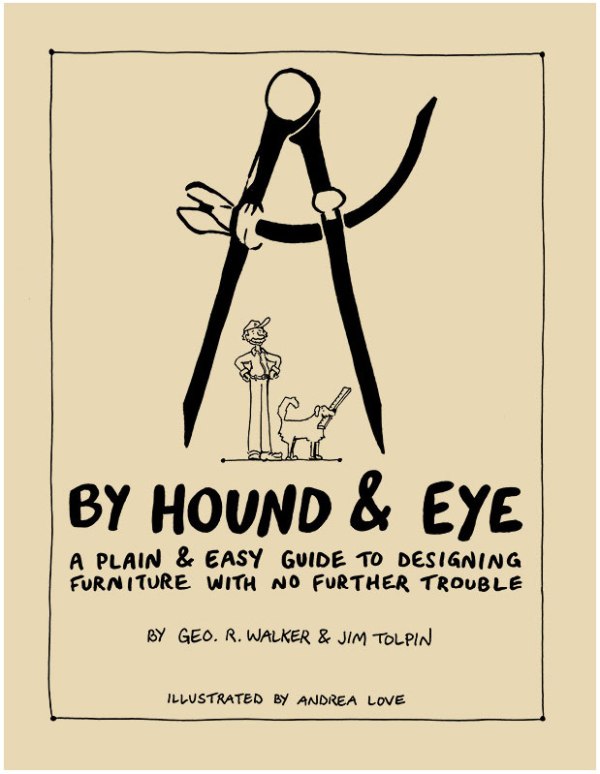

We are still cleaning up some 192 scans for the press, but this morning I finished work on both the front cover (above) and back cover of this fantastic workbook.

“By Hound & Eye” is, as I said, a workbook. If you follow the instructions of Journeyman and his sarcastic dog, Snidely, you will get a first-class education in the basic geometry required to design well-proportioned furniture. To do the exercises, which are fun, all you need is a pencil, a compass and a straightedge.

Even if you have nearly memorized “By Hand & Eye” (I have), you will find amazing new things to explore, especially when it comes to drawing fair curves. The explanation in this book is the best I’ve seen. And it’s even better that you are being schooled by a cartoon dog.

If you struggled with the concepts in “By Hand & Eye” or didn’t do the exercises, I think you’ll benefit from this workbook. If your nickname at the woodworking club is “Euclid,” then skip it.

The entire book is hand-printed and illustrated by Andrea Love, an artist in the Pacific Northwest. “By Hound & Eye” marks many “firsts” for Lost Art Press. Here are the details.

This is our first softcover book. The authors, George Walker and Jim Tolpin, wanted it to be something you would feel comfortable drawing in when doing the exercises. So we chose a paper that takes pencil marks nicely.

The authors also wanted the book to be durable so it wouldn’t fall apart while you are working. Most softcover books are merely glued together and the covers are ironed on. We wanted better.

So we are using our traditional sewn binding – plus glue and a woven fabric tape – to keep the pages together. You will be able to bend the binding so the book lays flat.

The book is 192 pages, 8.5” x 11” and produced entirely in the United States. The price will be $20. Sorry, but we cannot offer the workbook in a package deal with “By Hand & Eye.”

We are still trying to calculate if we can offer free shipping during the first 30 days it is on sale. Stay tuned.

More details (and an excerpt) to come.

— Christopher Schwarz