As a chairmaker, a small sliding bevel is essential to my work. The tool guides most of the joinery. It also is a companion when I explore historical chairs to understand how they work.

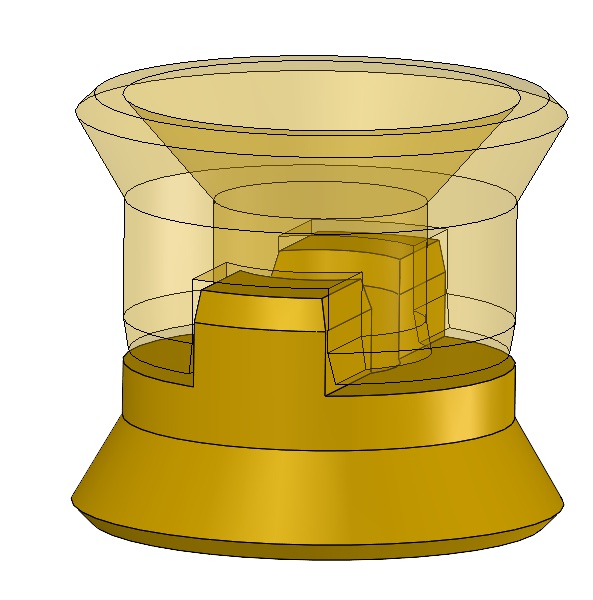

When we completed work on the Crucible Type 2 Dividers, designer Josh Cook and I wondered if we could adapt that tool’s ingenious tension/locking mechanism for a sliding bevel. The answer is yes. And thanks to tool designer and machinist Craig Jackson, we have a bevel in the works that exceeds any expectations I had for the tool.

The Crucible Sliding Bevel is unlike any other sliding bevel I know of. It locks the blade position so tightly that you have to be quite strong to get the blade to move off your desired setting. And if that’s all it did, I’d be happy. But it does something else, too.

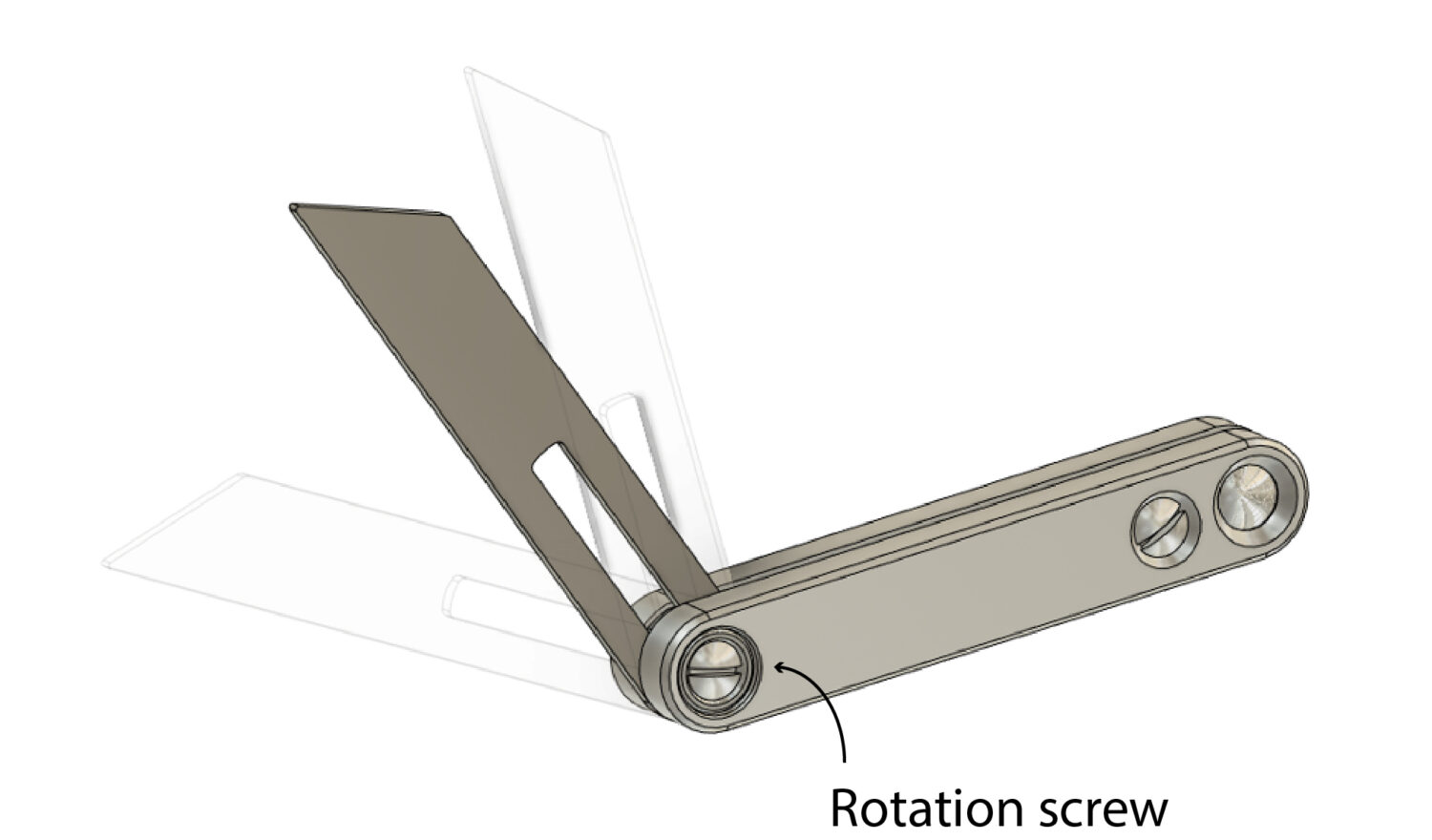

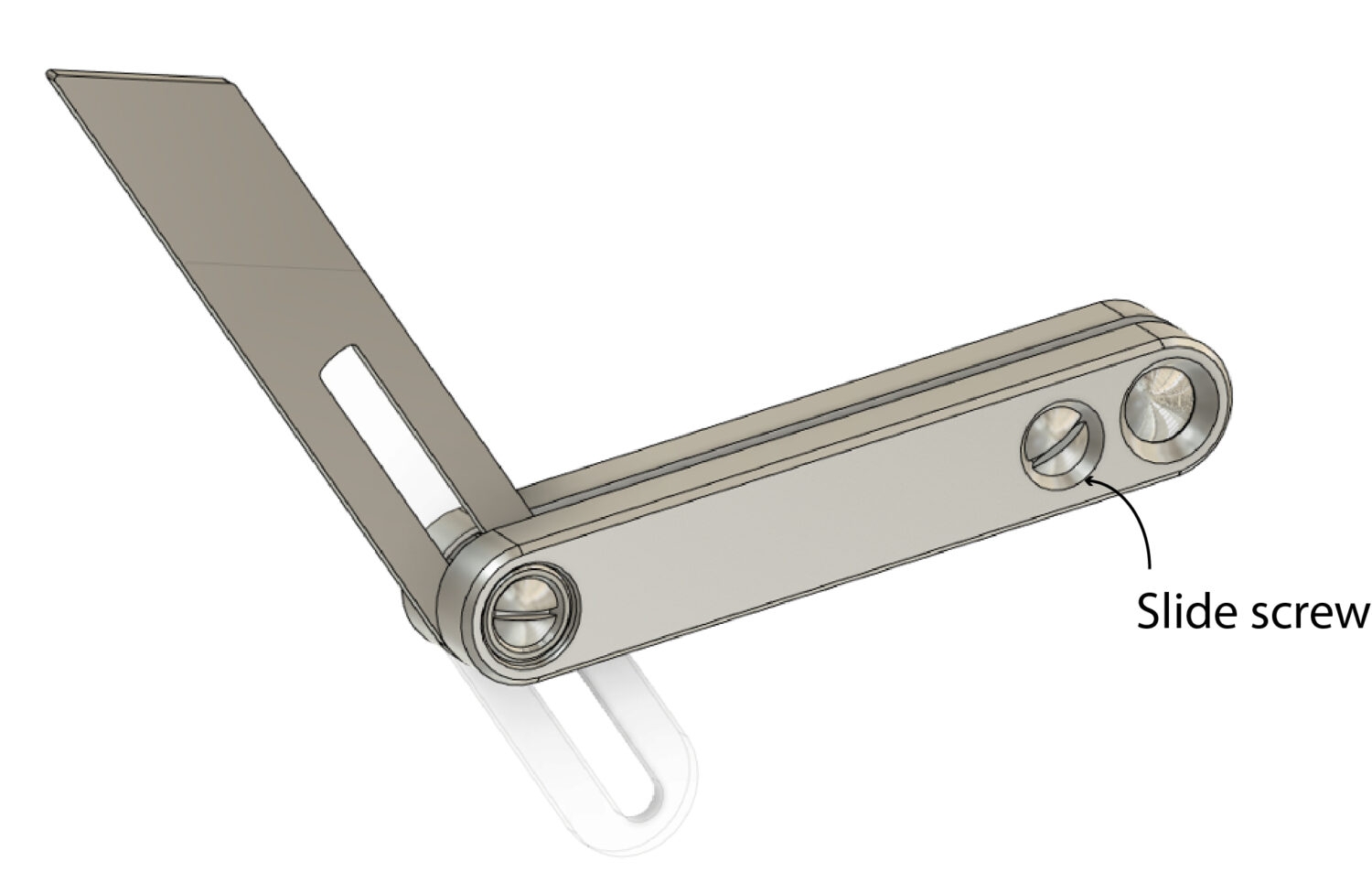

Thanks to Craig, the Crucible sliding bevel has dual controls that allow you to do some helpful things. The screw up by the blade controls the rotation of the blade. It works like the adjustment mechanism on any sliding bevel. You can use it to lock the blade, loosen the blade or set the tool’s tension so the blade rotates but with some effort.

The second screw near the back of the tool is used to adjust how the tool’s blade slides in its slot. You can use these two screws to control separately the rotation and the sliding of the blade. That means you can:

- Lock the rotation of the blade and then slide the blade to a different position in the body of the tool.

- Lock the blade so it won’t slide, but it will rotate.

I know this might sound complicated, but it’s not. Much like the dual controls on the Tite-Mark, my favorite marking gauge, these become second nature within a couple minutes. Also good to know: You don’t have to use the dual controls. You can simply use the control at the pivot point to work the tool – bringing in the second control only when necessary.

Some Specifications

We are making the bevel in alloy steel with a 4″ blade, which is my favorite size. The blade is 3/32″ thick, so it is impossible to mangle. The body of the bevel is 11/16″ x 3/4″ x 4-3/8″ and weighs a nice 10 ounces. The bevels are being made in Kentucky. The control screws are the same size as the screw on our dividers (so perhaps we’ll make a screwdriver soon).

One of the other nice things about this tool is that it is extremely easy to assemble and disassemble. So we will offer a 7″ blade that fits in this tool’s body in early 2022.

So when will these begin selling? We are waiting on a large steel order. The production fixtures have all been constructed and the programming is complete. Depending on when the steel arrives, there is a chance we will offer the first batch right before Christmas.

And the price? This is the most complex tool we’ve made so far at Crucible, and there is a lot of milling to make the custom parts. The retail will be $200, and I think the tool is worth every penny. (As always, if you’re feeling salty about the price, I encourage you to give small-scale domestic toolmaking a go. I love it, but sheesh – making stuff is hard.)

I don’t know if we have enough margin in these tools to offer them through our foreign and domestic retailers. But a few months of production will give us that answer.

In the coming weeks I’ll make a video that shows how the bevel operates.

— Christopher Schwarz