Question: What does that glass of Bulleit bourbon or Lagavulin Scotch have in common with a Chicago water tower and a wooden hot tub?

Answer: They all belong to the culture of tight cooperage, a subject on which John Cox is a fount of information.

I met John on a sweltering afternoon in 2018 while delivering a small piece of furniture to the Hudson Valley. Anissa Kapsales had invited me to meet her at John’s workplace, located in a large warehouse building on the outskirts of High Falls (population 627), about 90 minutes north of New York City. While I have long appreciated the fruits of the distiller’s art, I confess I hadn’t given much thought to the oak barrels that play such an important part in their production. John was the ideal person to enlighten me; a polymath with the personality of a showman and boundless enthusiasm for his work, he’s a natural teacher.

John was born in Philadelphia in 1969. His father was a tool and die maker who’d followed in his own father’s footsteps. They hoped John would become a doctor and not work with his hands. Oh well.

In high school John played music. He attended Muhlenberg College for a year of pre-med studies, then transferred to the Esther Boyer School of Music at Temple University. Many of his fellow students had been studying music seriously for years, and he soon realized that he was not in a position to compete – he’d never get a chair or play on Broadway. However, he knew some luthiers and thought “if I can’t play, I can build.”

He did a traditional apprenticeship with Richard Buccigrosse and John DelVecchio, who ran a millwork shop in his South Philadelphia neighborhood. Richard made flamenco guitars, in addition to fabricating millwork and repairing antiques. Richard was very strict – the shop culture was closer to that of a Philadelphia furniture shop in the 18th century than in the 20th. John worked full days in the shop, unpaid, then went to his job as a short order cook in a diner.

Affordable shop space was plentiful in Philadelphia in the 1980s; the recession had hit the area hard. John opened his own shop, and Richard sent turning and millwork jobs his way so he could spend more of his own time on flamenco guitars. On weekends, John took finishing classes with George Frank (author of “Adventures in Wood Finishing”) at the Olde Mill Cabinet Shoppe on the outskirts of Philadelphia.

Meanwhile – and this is where John’s story starts to sound like a Who’s Who of woodworking – the Snyderman Gallery, located a couple of blocks from John’s shop, was regularly exhibiting studio furniture. John developed a niche as a finisher, catering to local studio furniture makers and doing repairs and touch-up for the gallery. He specialized in ebonizing, French polishing and work with color, using a lot of aniline dye. At the age of 21 he found himself repairing a Gary Knox Bennett desk. Several graduates of Wendell Castle’s school had opened a group shop in Fishtown; John became the finisher for the group and worked with Michael Hurwitz and Peter Pierobon, among others.

In 1994 he took a job as foreman in a finishing shop, Finish Resources Studio, in New York City. They developed specialty finishes for designers, such as cerusing (decorative pore filling) for Tom O’Brien of Aero. “George [Frank] taught me the process,” John says. “It was us in the workroom that developed it.”

Four years later, he met Danish craftsman Jan Engberg and his son, Ian, who had a shop making high-end furniture; John ran their finishing shop from 1998 to 2001. “For the fourth or fifth time in my life, I find myself working with an old European master,” he says with appreciation for these opportunities. “I kept falling into these relationships with them, sort of avuncular. I’m very fortunate – to be working with these insanely talented older Europeans.” Working for the Engbergs, John did jobs for high-end interior designers such as Steven Harris (a protégé of Robert Stern) and Lucien Rees-Roberts. “Everything got published – Elle Décor, Architectural Digest. This was before Instagram,” he adds as a slightly wistful side note (that’s quite familiar to me). “We would never get pictures of anything unless it got published.”

Lucien designed some “wacky stuff,” says John, that was inspired by 20th-century designers Jean Michel Frank and Samuel Marx. They used a lot of goat skin, cow hide, leather, parchment and gilding, and produced pieces destined for swanky apartments in such upscale areas as Central Park West. Recalling the kinds of orders they got from the designers, John says “’Let’s do the rosewood tables we did for the last client…let’s do the leather closet doors we did for Cabo – let’s do that for this client, but bigger.’ They sent me to Cabo right during the mad cow disease outbreak … with 42 cow hides! I feel like we worked for everybody that ran Lehman Brothers,” as well as entertainers such as John Leguizamo. “They flew me all over the world. It was all custom work.”

Then came 9/11. “We stood on the roof of the shop and watched it go down,” John says. “It affected our business. I wanted to leave New York.”

At a finishing convention in St. Paul the following year, he met Greg Johnson, who worked for Wendell Castle. Wendell had opened up a 42-man furniture factory called Icon Design outside Rochester; they were so busy they’d reached a bottleneck in production. Greg asked John to join them, and he did. As you’d expect, the work was meticulous. Each piece involved about 21 quality control checks, right down to razor-fine specs for the sheen of the finish. While working for Wendell, he met the sculptor Albert Paley and took on jobs for him, too, flying to installations around the country where a piece of work needed repair due to damage suffered in a move.

The downside: all of this work involved a lot of chemicals. John was spraying urethane and lacquer – “doing great things that were not good for me. But I got really good at it and got a reputation…”

After a year in Rochester, he was ready for a change of scene. They moved to the Hudson Valley, where John opened a one-man shop combining restoration work with commissioned pieces like a goatskin side table. He found himself running all over the area for jobs that barely paid the bills. Even with freelance gigs for Albert Paley, it was tough to make a living.

One day in 2015 John was talking with a friend who planned to open a mushroom-growing operation. “I said ‘I’d love a change. Why don’t you bring me in?’” His friend suggested something different. “Do you know there’s a barrel crisis right now? Why don’t you make barrels?” About a week later, Time ran an article about the barrel shortage, which has been exacerbated by a federal mandate that American distillers must use newly charred oak – in other words, a whisky barrel gets one-time use. Kentucky cooperages couldn’t keep up – they were working with lead times of 18 months. Craft distilling was a burgeoning business, but distilleries couldn’t find barrels.

John discovered that there was scarcely any information available on how to make barrels. Fine Woodworking had published an article about coopered joinery, and he found another on coopering by Tage Frid, but that was about it. It was truly, he says, a lost art. “So I bought three different barrels from three cooperages, took them apart and reverse-engineered them. It was a cipher. What’s the formula? It was like a cryptogram.” A cryptogram indeed – the research and development for Quercus Cooperage took more than two years. In the meantime, John was still running his furniture restoration business.

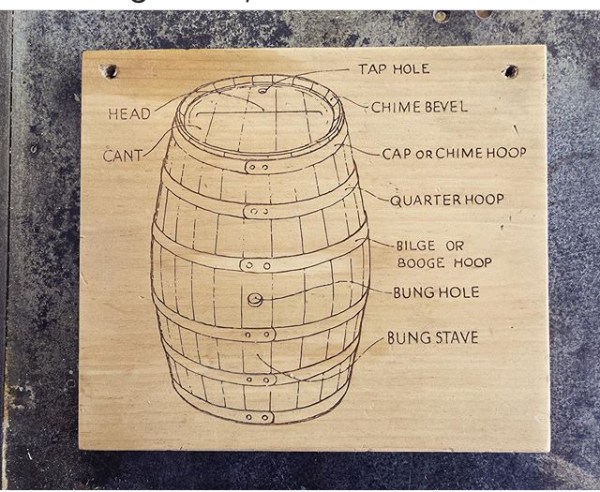

There are three types of coopers

1. Tight coopers make watertight containers.

2. Slack coopers make containers for dry goods. Everything shipped in the 19th century went in these containers, which were made by giant factories – nails, cotton, tobacco, salted meat and fish, gunpowder, oysters, fruit, cement.

3. White coopers have traditionally made household containers such as buckets, butter churns, bowls and pails. In Japan, white coopers made koji trays.

When he heard about a large collection of 19th-centuring coopering tools for sale by a museum in Ottawa, he bought it. Then he set about learning what each one was, and how it should be used. “There was every tool you would need in a cooperage. Some looked familiar; some I had no idea what they were. Eric Sloane had some of them in his books; one of the first books Taunton did was a republication of a book of tools from England. I identified some from that.”

Next, he worked to figure out how to get his 20th-century machine tools to do what these hand tools did in the 1800s. “I held these 19th-century tools in my hand and said ‘How can I get my 3-horsepower shaper to do the same thing?’ How would I make this stave?’”

Here’s where his jazz background came in handy: there’s a lot of math in both fields. “Embracing the mathematics behind it really helped me figure it out,” he says, noting that Johannes Kepler had laid the groundwork for calculus by trying to figure the volume of a wine barrel. “It was becoming an obsession.”

He broke the process of barrel-making down into five stages:

1. Acquire and air-dry the wood. It has to be air-dried, not kilned. He bought locally grown oak logs and had them quartersawn, then stickered.

2. Mill the staves. He had shaper knives custom-ground.

3. Find the steel for the rings, then make the rings and hoops.

4. Toast and char the oak to the client’s specifications. Toasting the sugars in the wood is an art that can make or break a whiskey.

5. Assembly. The point is to make a watertight cask. “It can’t even have a pin hole.”

On Dec. 22, 2017, the Winter Solstice, John succeeded in getting a barrel to hold water for the first time.

He’s now one of 33 cooperages in North America, and he makes his barrels largely by hand. A cadre of “meddling woodworking friends, machining savants and a welder” have helped along the way. As with most highly skilled custom work that uses top-quality materials, the economic side of the business remains a challenge. The wood for a barrel comes in at around $150. You can buy a barrel for less than half that from a major manufacturer.

John recently expanded into another of the traditional cooper’s arts: tanks for fermentation. Stoutridge Vineyard and Distillery, his regular client in Upstate New York, asked for an 800-gallon tank, the kind used for Scottish whisky. Adds John: “That’s also what the soy sauce guys ferment in. Before Covid hit, everyone was starting to make shoyu. But no one’s making barrels for shoyu; they were using stainless steel. You’re not going to get the flavor profiles you want from fermenting in steel. In Japan they use open-tank traditional wooden fermentation. No one makes them here.” He made a 2-gallon prototype, and things took off.

“I pivoted into this culinary world. This koji thing that’s happening – they’ve been fermenting rice for 7,000 years. No one in America was making koji trays. If I hadn’t pivoted into the culinary stuff last fall I don’t know where I would be now.”

Brad Leone of Bon Appetit discovered John through Instagram; a chef John knows had asked him to make koji trays, and his name and pictures quickly made their way around that community. “They came to the shop and posted some stuff and it really blew up. [People] want to do this traditional Japanese work” – think sauerkraut, or kimchi – “but they don’t have the traditional objects to make it.”

Still, he says, it remains challenging economically. Margins are slim. “I’m a struggling one-man shop no different from any other.” Every barrel is custom made and takes time. Even with the technical challenges involved in figuring out his methods, John says the biggest learning curve has related to shipping and logistics. Instagram has helped him market the work; it’s one thing to get press in a print magazine, but there’s a two (or more)-month lag between the writing and publication. There’s no lag-time in Internet publishing, which makes it easier to change course swiftly.

Because of Covid, John’s craft distillery and brewer clients are closed, so the culinary stuff is filling his time. There’s a market, for now; it’s also more affordable. He says he’s the only person making the small tanks in America right now and adds, “I’m 5’6” so they actually call me a mini cooper.”

—Nancy Hiller, author of Kitchen Think and Making Things Work