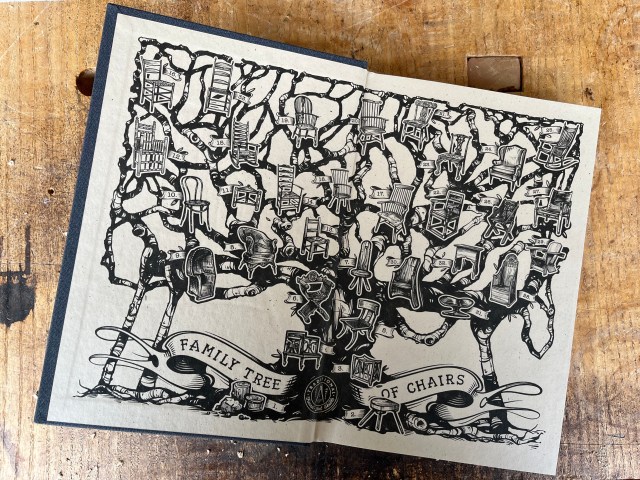

Plate Courtesy of John and Eleanor Kebabian

Any time a picture or video shows up of Chris or me or a student using the low bench to shave spindles, I get questions about the “planing stop” against which the workpiece is held. That’s the “Hulot Block” or “head” that shows up in 1775 book “L’Art du Tourneur Mécancien.” Chris reproduced it for the Roman bench in “Ingenious Mechanics.” It’s on page 97 in Chapter 5: Early Workholding Devices. (There are many other simple and clever workholding devices in that chapter, too – but this is the one that always catches people’s collective eye, and it’s the one that sees the most use in our shop.)

– Fitz

If the shaving horse seems too complex, consider shaving spindles and legs using a setup from M. Hulot’s “L’Art du Tourneur Mécanicien” (1775). Hulot details a low bench he calls a “saddle” for chairmaking. The bench includes a “head” for shaving pieces and wedge-based clamps for holding chair pieces.

Plate Courtesy of John and Eleanor Kebabian

To shave pieces, you don the “belly” in front of your belly and immobilize the wood between the belly and the head, as shown in the plate above.

We translated the original text (thanks Tom Bonamici) and offer it here for you to interpret.

The Figure 4, Plate 13, represents a type of bench which is named a Saddle for planing and assembling; it’s a piece of oak of 5 feet in length by 12 to 14 inches in width, and very thick, carried on four strong legs below, R, Y, X, Z, which enter through as many round holes drilled in the bottom of the Saddle, A B. The Worker has his face turned toward the head, H B, which is a big piece of softwood, such as alder, and of which the bottom forms a flat tenon which passes through a mortise in the Saddle; the upper part [of the alder head] forms a type of stepped stop, of which the steps are notched in different ways, some perpendicular and shallow, for receiving the end of flat pieces to be planed on their edge [see vertical notch just to the left of the letter B, Fig. 4, Pl. 13]; the flat steps receive pieces to be planed on their face. Other steps are notched horizontally and vertically in the form of a little spoon, for receiving the end of a baton. There are more little vertical notches next to this hollow, which can be seen in the figure [Fig. 4]. Independently of the tenon which fixes the head H, it [the head] is supported by the cross beam K, also named the transom, head, or buttress of the head, & which is supported at the end & across the Saddle, by two strong pegs of strong and binding wood, such as ash or dogwood, which pass perpendicularly across the cross beam and the Saddle.

Photo by NN

If the wood to be planed is big & long, one doesn’t sit on the Saddle, but one stands upright, & one places the end of the wood in the corner H K formed by the cross beam and the side of the head of the Saddle.

The Worker is obliged, in planing a piece of wood, to support its end against his stomach; & so as not to hurt himself, he has in front of him a mass or block of wood that’s named the Belly.

This Belly is a type of wooden piece of oak, a foot long, 6 inches wide, & about 1/3 of an inch thick, Pl. 13, fig. 10. The top part is cut in a roughly oval shape, F I, f G; the bottom part, F I, f k, is made in a roughly semicircular shape; & as the Turner places this Belly in front of himself, the cord of his apron passes from F to f, and by this method the Belly is held fast. In the middle of the oval, one places a block L, of softwood, round, 3 to 4 inches in diameter, by around 2 to 3 inches in thickness, made of end grain, and in the center of which has been inserted a pin l of hardwood, & which is held by a friction fit in a hole in the center of the Belly’s oval; one cuts the end of this pin flush off at the back so that it doesn’t hurt the Artist. On the face of this block, one makes a very shallow groove in the shape of a cross, which serves to hold the flat pieces to be planed, either on their face or on their edge. See Pl. 31, vignette, fig. 3, where the Turner is occupied in planing. Below figure 10, Pl. 13, we see the block shown in perspective; l, is the tenon or pin which enters in the hole in the middle of this block. The holes I, I, which are at the bottom, in the semicircle of these Bellies, serve to hang them on the wall when not in use.

Photo by NN

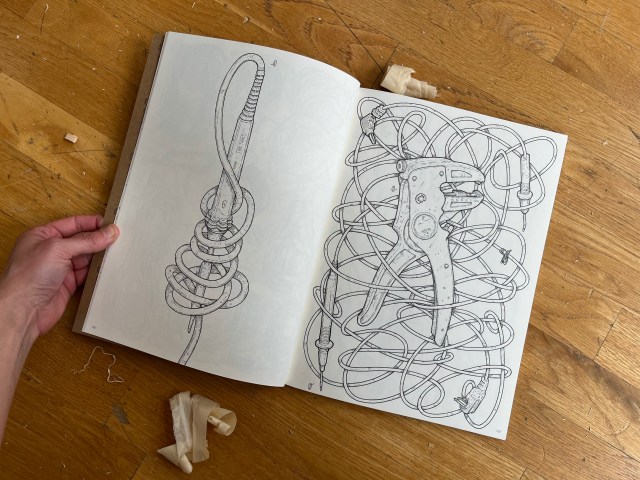

Making the head is simple. Like the shaving horse, the palm and the planing stop, these fit into a 2″ x 2″ mortise in the benchtop. Construction begins with a post that is 2″ x 2″ x 9-3/4″. Plane it so it fits into the benchtop mortise with mallet blows.

Now mortise the post into the 3″ x 3-3/4″ x 5-1/2″ head. Cut a mortise that is 3/4″ deep. Glue the post into the head.

Cut a series of rabbets in the head. I made mine roughly match the plate in Hulot. There also is a blind hole in the middle and a few kerfs. All these notches and kerfs are used to hold onto one end of the work. And, judging by the plate showing the head in use, you place the stick’s tenon in the hole when working a spindle or leg.

The belly is a thin plate of wood that you wear – like an armored breastplate. A block of softwood with two trenches plowed across the end grain serves as the other end of the clamping action.

Hulot specifies that the block is friction-fit into a hole into the breastplate, which I assume will allow the block to rotate (if needed).

I made the breastplate from a thin piece of poplar – 1/2″ x 10″ x 14″ cut to a rough oval shape. The block is white pine – 4″ in diameter x 2-3/4″ long. The 3/8″ x 3/8″ trenches cross in the middle of the block. I attached the block to the breastplate with a large screw, which allows it to rotate.

Hulot says the worker’s shop apron string can secure the belly while working. However, my shop apron doesn’t look anything like the aprons shown in the plate. So, I riveted the belly to a pair of $6 suspenders (a couple screws could also do the job of the rivets).

If you are shaving only a couple of pieces, you can prop the belly up on your legs. For long sessions, you’ll want it tethered to you in some way.

The belly is remarkably effective for shaving legs and other chair components. The block holds the work so you can knife the end of your workpiece without the drawknife’s handles hitting your body. Also, the rabbets on the head are all useful – especially the small rabbet at the top, which allows you to shave small components along their entire length.

The belly is an effective alternative to a shavehorse in many cases. It can be used at a high or low bench. It takes up no floor space. It allows you to shave the entire length of a leg or spindle in one swipe. It’s as fast as a shavehorse.

It’s not as effective when dealing with long, thin spindles, such as the 5/8″-diameter back spindles on a Windsor chair. They are so long and flexible that they are a handful when using the belly.