By Suzanne Ellison

He was deeper in the forest than he would normally venture and felt a sense of unease in this unfamiliar wood. The weak daylight of late October was fading away, and he didn’t see the tree stump until it was too late. He caught his foot on the stump and fell hard onto the cold ground. As he got himself up he saw the trunk of a tree and several logs scattered nearby. Not seeing any markings identifying the logs as belonging to the King, he packed them on his sled and, with a a sore ankle, made his way home.

As he came through the door of their small cottage he saw his young daughter tending to a small kettle hanging over the fire. She turned toward him and exclaimed, “Papa, you’re home! Jacob and his grandfather came by this afternoon, and we are having rabbit stew for our supper!” He was relieved they would have a hot meal and felt ashamed he wasn’t providing for her as he wished. He smiled at his little girl and saw how much her eyes were like her mother’s and her smile like his. She continued, “Jacob’s grandfather asked if tomorrow you could help him repair their roof.” “Yes, of course I can. I’ll head over first thing in the morning,” he replied.

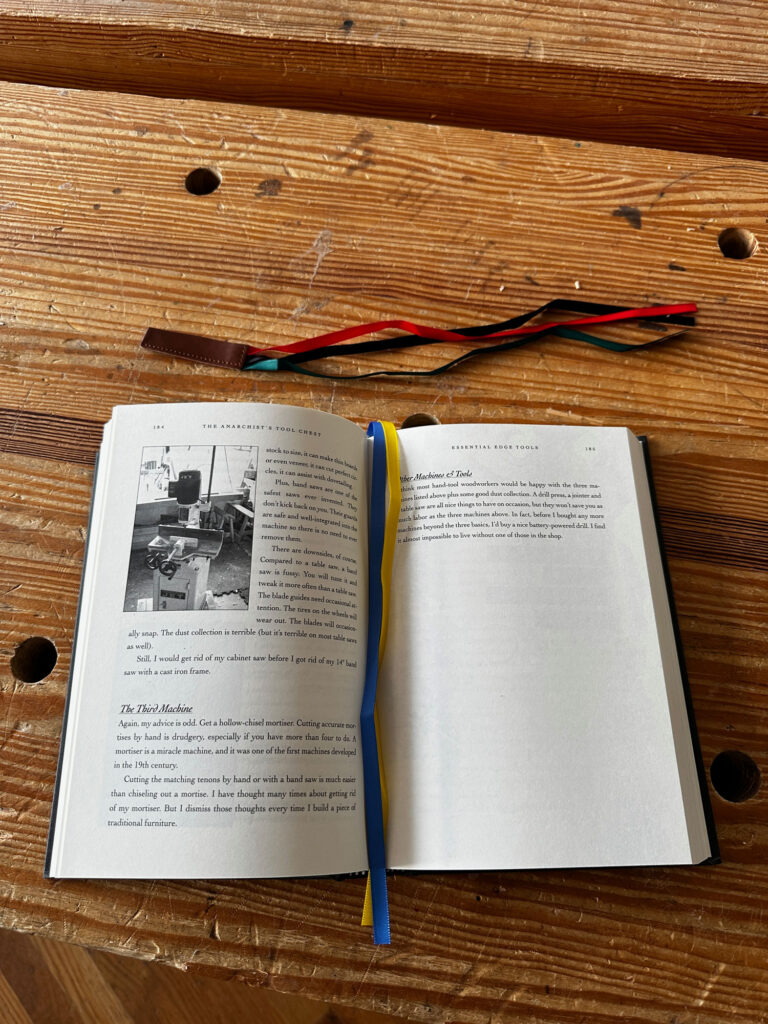

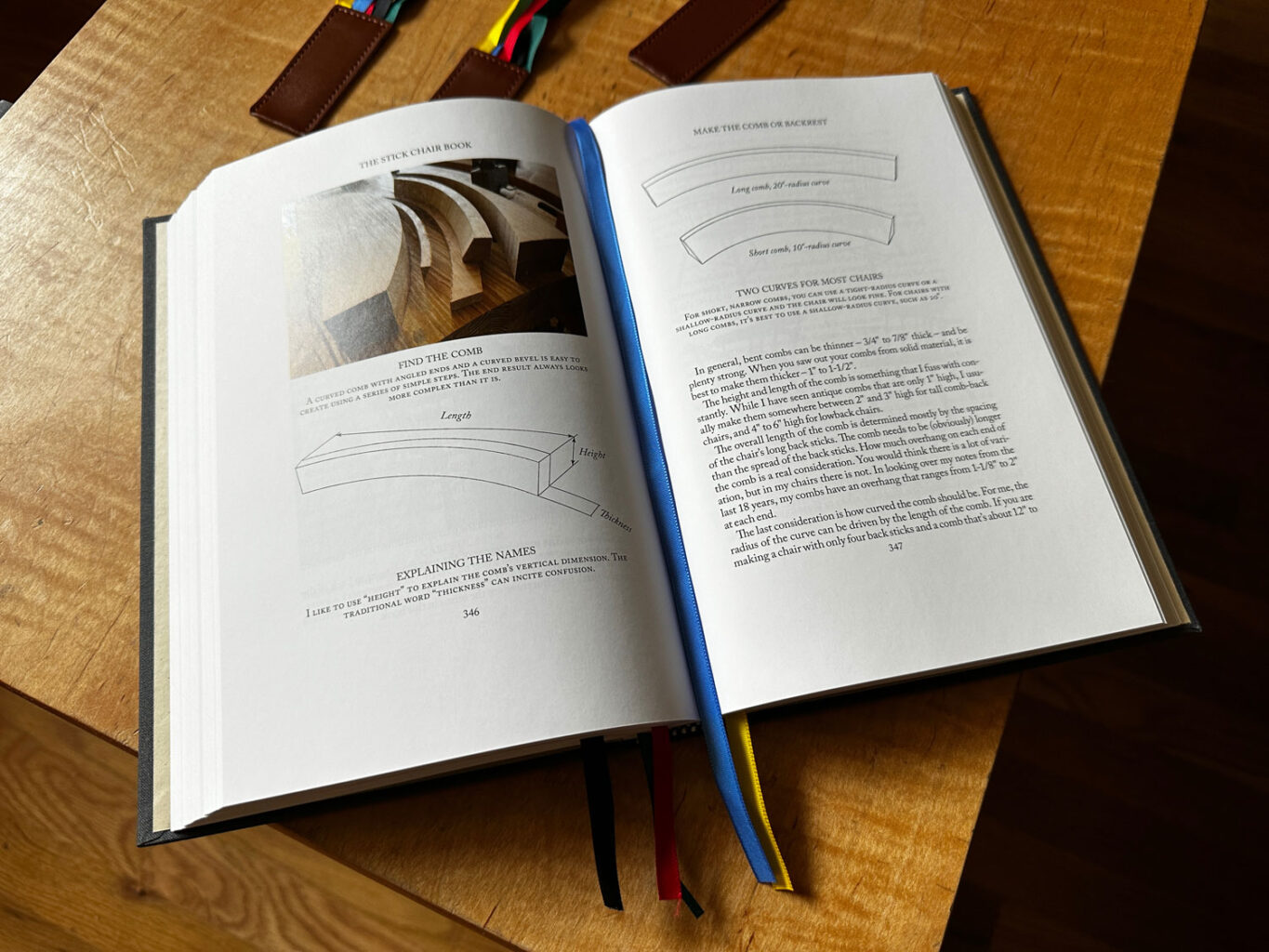

After their supper he spread a heavy cloth on the floor in front of the fire. He brought the logs over to examine them in the light. The bark was smooth and dark with a scattering of bumps. The edges were not fresh, and the weight of the logs indicated they had probably been cut a season or two before. He trimmed one end of a log, saw the wood was a pure white and was fairly certain this was holly. On two of the larger logs he could just make out that each had been incised with an ‘Θ.’ This was strange as trees and lumber for the King’s use were marked with white paint. He ran one finger over an ‘Θ’ and with a sharp intake of breath quickly pulled his hand back. Had he been stung by a wasp? His finger stung and bled and he saw a splinter lodged in his fingertip. “I hope you have no more surprises for me,” he said to the log. “A sore ankle and now a finger. That’s quite enough mischief from you.” He gathered a few tools from a small chest in the corner and started to process the logs. He thought there would be more than enough wood to make a small table.

The table would be plain, nothing fancy, a place to have their meals together. His daughter could set out her sewing, sort the herbs she used for cooking and they could play games. It would make their home more comfortable. Before he knew it, his daughter was saying good night and climbing the ladder to the loft where she slept. A few hours later he had the stock he needed. He cleaned and put away his tools. Tomorrow, he would try to match the wood to make a pleasing pattern on the tabletop.

The next day he helped his neighbor repair his roof and a stable wall. His daughter helped in the garden and kitchen. In return, they came home bearing fresh bread, pots of berry jam, a basket full of vegetables and a couple more rabbits. That night they had a merry time over their supper.

After supper, he sat back in an old upholstered chair, the last piece of furniture they still had from their old home in the city. Although the cottage was warm his body kept a memory of the cold day. His face stung from the sharp wind and his hands were sore. Well, he thought as he sat up, I can at least sort and match the stock for the tabletop. After a few tries he called his daughter over. “What do you think?” he asked. Yawning, she came to take a look. “That will make a fine table,” she said and asked, “How will you remember which pieces of wood go where?” “I’ll make a special mark to help me match them again when the pieces are glued and put in the clamps,” he explained. “A special mark? Is is magic? Can I see it?” she asked. “No magic and you can see it tomorrow morning. Now, get to bed and Good Night!” he answered.

With the matched pieces laid out on the floor he drew the cabinetmaker’s triangle. To the unfamiliar eye, it looked like a fancy triangle with a center line and some loops. To him, it was a enjoyable reminder of another time. When he was first introduced to this method of marking wood he thought it was magic, and in saying so, received a smack on the back of his head from his master. Sitting back on his heels he laughed at the memory and said aloud, “I said it back then and I’ll say it again, it does look like a witch’s hat.” He glued the wood together and set the clamps. That done, he sat back in the old padded chair with his feet toward the fire. He dozed.

“You were not wrong, it is a witch’s hat,” said a low and dusky voice. He woke with a start. “Who said that? Show yourself! We have nothing worth stealing!” His eyes cleared and the room seemed smoky, but not from the fire. The clamped wood for the tabletop seemed to move. The point of the cabinetmaker’s triangle tipped outward as it would if someone were about to rise from a seated position. His eyes cleared, and he saw the entire mark lift out and up from the wood. On either side of the mark two long-fingered hands emerged and appeared to push away from the wood as a shimmering figure formed in front of him. He saw a woman with long, black hair wearing a gray gown. The air around her moved like a veil making it difficult to see her features. He stood up and saw she was almost as tall as he. “Who are you and what do you want? How did you get in?” he demanded. She laughed at him, “You just saw me come hat-first out of the wood. I am released!” She flung her head back and twirled around causing the air in the room to swirl around her.

“What are you?” he asked. “Oh, I was ‘a who’ and now ‘a what.’ How rude!” she remarked. “Answer the question!” he demanded. “As you can see, I’m wearing the hat and I am a witch.” She twirled around once more. Stepping closer to him she raised her hand and pointed one long finger toward him. He could now see her face. It was thin with high cheekbones and flat, black eyes. Her lips were full; her chin came to a rounded point. “Like what you see?” she teased. He thought she was repulsive and answered, “Not in the least.” Moving a step closer, she extended her hand and with a long, black fingernail gave a sharp tap to his chest. “Oh, that is too bad,” she said with pouted lips. “You,” she continued with a low laugh, “drew the mark and released me from the holly.” Stunned, he stepped back and almost stumbled. “That’s impossible!” he countered. “Holly is used to ward off witches not conjure them!” “For me, the holly was used for another purpose. It took the power of six wizards to bind me. They locked me into the holly to prevent my escape. I was legendary,” she explained with a note of pride in her voice. In a much lower and anguished voice she added, “It was agonizing.”

“When did this happen, how long were you in the holly?” he asked, not that he would believe anything she said. “In your measurement of time, about 200 years. The tree was marked with a warning to never cut it down. It seems someone forgot,” she explained. He didn’t want to know what she had done to be magically bound and locked in the holly. He thought about the two marked logs. “That’s why,” he started to say and stopped. “Why, what?” she asked. “It was almost dark when I found the logs and didn’t see any markings. Later, I saw that two of the logs had a mark carved into the wood, a circle with a line in the middle.” “Ohh, too bad for you and too good for me!” she laughed and added, “That is an old symbol meaning death and a warning to stay away from the tree. It seems it was ignored.” “Or not recognized to be a warning. I’ll take the wood back to the forest in the morning,” he replied and wondered to himself where would he find more wood.

“The wood is fine. Now that I’m released the wood is harmless, well, harmless to you. I never again want to see a holly tree. Make your table,” she said and turned to look around the cottage. He watched her touch and turn a few objects before she turned back to him. “As you released me from the holly I am required to give you payment,” she started to explain. He quickly cut her off, “I don’t want anything! Just go and leave us alone!” he responded. “By us, you mean you and your young daughter? If nothing for you, what would you like for your daughter? It’s a dangerous world for young girls. I can protect her and make sure she is happy,” she offered. He shuddered at her words. “We want nothing of your witchcraft! I won’t make a deal with you! Go!” he shouted. She had seen this reaction from ungrateful humans many times before and was non-plussed. She drew herself up and looking him straight in the eyes said, “Have it your way, for now. I will see you 20 years from this night, and on that night you will thank me. And, I promise to curse you!” Then, she was gone. The air cleared and the tension left his body. He sat heavily in his chair and slumped back. What had just happened?

The next morning he woke with a start and rushed over to the clamped wood. The cabinetmaker’s triangle was still there, but the lines were smudged and not as sharp as when he first drew them. Before starting work on the table he cut pieces of holly and went outside to nail some over the cottage door and each window. Over the next few days he worked the wood and made the table. With the table finished, he returned to the forest and brought back more wood from the fallen tree. He used the holly to make tall cases for either side of the fireplace. And, he kept track of the years by making a small mark on the highest shelf of the case closest to his chair.

When others saw the kind of work he could do he was asked to make tables, chairs and chests. With each job he was able to buy wood and no longer needed to scrounge in the forest. Years later, when his daughter married, the holly table was part of her dowry. On the day his daughter and new son-in-law drove away with their wagon loaded with the holly table and other furniture he had made, he tied several small holly branches together and handed them to his daughter. “Remember,” he started to say. “Yes, Papa,” she smiled and continued, “nail one sprig above the front door and above each window. We won’t forget!”

Days before the 20-year mark, he pulled an old blanket chest before the fireplace. Every few years he and his daughter would decide which piece of furniture could use a new coat of paint or a new design. The blanket chest was a faded blue with white, red and yellow flowers dancing across the top. He ran his hand over the flowers, remembering when his daughter painted them. He pictured her little face serious with concentration and the tip of her tongue just sticking out. Oh, I can’t paint over her flowers, he thought, it will have to be something else. He looked around and his eyes settled on the tall case by the fireplace. You’re next, he thought, but not tonight, I’m too tired.

He was in the cottage the night that marked 20 years since the witch had first appeared. The tall case was propped up on two sawhorses and he was removing the shelves. Still undecided on which colors to use he had placed several paint pots and brushes to the side. With the shelves out he sanded a few rough spots. The room cooled, a faint whiff of smoke stirred in the air and he knew she was about to arrive. Suddenly, she was in front of him. Her hair was no longer black, rather the gray of weather-beaten wood. Her face was thinner, almost skeletal, and her eyes held great malevolence. He thought she must have done terrible things to have gained that degree of evil. “Oh, I see you are still busy making things! What is it?” she asked as though this was any normal evening and she had just popped in for a friendly visit. Her voice was still low, its dusky tone replace by a creak. “It’s a case to store things. I took the shelves out before freshening up the paint,” he answered. “Well, that sounds like a dull job,” she remarked in a flat voice.

“Would you like a drink? A brandy?” he offered. “Yes, please. It would be welcome on this cold evening. After that, as I told you 20 years ago, you can thank me,” she answered. While he poured the drinks she looked around the cottage and asked about his daughter. “As you well know, she is fine. I heard an old woman would occasionally stop by and ask for a drink of water. There were also times when I was told about strange happenings, such as the ground around her cottage being perfectly dry just after a heavy rain. You shouldn’t have done that,” he said, his voice steely. “Oh, there was no harm, just making sure she was happy and healthy.” she replied. “So, she doesn’t owe you anything?” he asked. “No, well, maybe just a little bit,” she said as though she was teasing. He knew better. She had come to collect something she wasn’t owed.

They each had a second brandy followed by another. He smiled, leaned back and hummed a tune he had recently heard at a wedding. “I like that, what it it?” she asked. “A country dance tune, do you want to dance?” he asked and stood waiting for her to join him. He took her hands and swung her around and around in smaller circles until he had her in his arms. She threw her head back and laughed. His arms tightened a bit around her. “What are you doing?” she gasped. “Dancing, just dancing,” he smiled back at her and held her closer. “You go too far! I will curse you!” she warned, “I will curse you to oak!” He laughed at her, unfazed by her threats, “Oak? A good, strong wood.” He looked down into her eyes, challenging her, and she saw he had no fear of her. She hissed. In moments, he felt the back of his neck tighten, followed by his shoulders and arms. He watched, fascinated, as his arms became wood bringing her tighter against his chest. She twisted frantically and demanded to be let go. He looked down at her, “I can’t, and now you are coming with me.” She screamed and struggled as the his oaken arms slowly squeezed her. His legs heavy, he lurched toward the tall case and leaned so as to tip them into it. Her screams grew more strident. “It’s holly!” she shrieked and writhed in agony. “Yes, holly from your old trees and, thank you,” were the last words he spoke before he turned entirely to oak and she to holly.

Her father had been in poor health in the last month, and she worried he was not eating enough. She entered the cottage, feeling the cold and saw the fire was out. Stepping forward, she called out to her Papa. Another step took her to the edge of the tall case. She remembered when they had painted the cases. They had just finished when, laughing, he had said, “When my time comes remove the shelves and use my case as a coffin, but please repaint it! This rose-red will not do!” Through her tears she looked down at him and promised, “Oh, Papa, I will paint your coffin your favorite blue.” She leaned closer and stroked and kissed his cheek. His mouth was curved in a half smile and a small holly log was clutched tightly to his chest.

Like this:

Like Loading...