One of the (many) barriers to making staked furniture or chairs is wrapping your head around the compound-angle geometry. And then figuring out how to execute it at the bench.

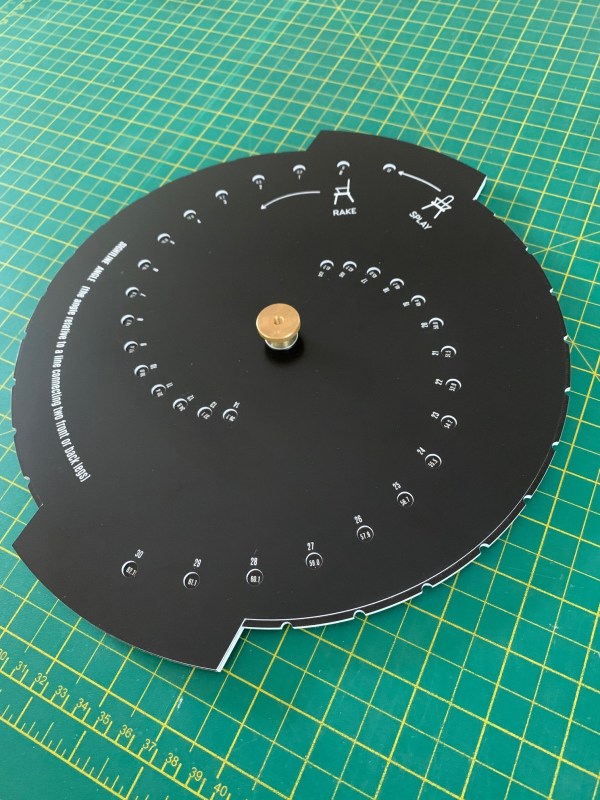

The new Crucible Chairpanzee ($16 plus shipping) does the trigonometry for you, allowing you to translate rake and splay into sightlines (which create your layout lines) and resultant angles (which is the setting of your sliding bevel).

This allows you to easily design new pieces of furniture with compound angles and to replicate angles from existing pieces of furniture from photos.

The Chairpanzee is a clever sliding calculator that is printed and assembled in the United States. Here’s how we use the Chairpanzee on a chair design (though it can be used for tables, stools or any other piece of staked furniture).

To calculate the “sightline:”

1. On the underside of the seat, draw a line connecting the two front leg mortises (as shown above). This is the baseline.

2. Move the calculator’s slider to the desired splay angle in the top window.

3. Next to the lower window, select the desired rake angle. The number shown in the adjacent window is the sightline angle.

4. Draw the sightline angle on the underside of the seat using a protractor. The 0° on the protractor should be directly on your baseline.

5. Repeat steps 1 through 4 for the rear legs.

To calculate the “resultant:”

6. Confirm that the calculator’s slider is set to the desired splay angle in the top window.

7. Next to the lower window, select the desired rake angle. The number shown in the adjacent window is the resultant angle.

8. Set your sliding bevel tool to the resultant angle and place it directly on the sightline on the underside of the seat.

9. Drill your mortise. Keep the drill bit perfectly parallel to the blade of the sliding bevel.

The Chairpanzee is available for immediate shipment. We hope that some of our retailers will also carry this product for our international customers.

In the coming week I’ll post a video that shows how it’s used.

— Christopher Schwarz

Like this:

Like Loading...