The following is excerpted from Christian Becksvoort’s “With the Grain: A Craftsman’s Guide to Understanding Wood.” The three woods I chose (from the 30 he covers) are my favorites from which to build tool chests, because they are lightweight and relatively inexpensive (and because they have a good “mash factor,” and thus can make you feel like a demi-god dovetailer – if your joints are technically a smidge too tight, they can be squeezed together, no splits, and look perfect).

“With the Grain” is the book about wood that we wished we’d had when we started woodworking. It is, above all, succinct, easy to understand and perfectly suited for the furniture-maker. As important as what is in its 160 pages is what is not. It’s not a detailed analysis of cell growth. It is not a heap of tables and equations for figuring truss loads in residential construction. It is decidedly not a scientist’s approach to the material. Instead, “With the Grain” contains the facts you need to know at the lumberyard, in the woodlot and in the shop. It gives you enough science so you understand how trees grow. It explains the handful of formulas you have to know as a furniture-maker. And it gives you a hearty dose of specific information about North American species that will inspire you.

– Fitz

Woodworkers should have a rudimentary knowledge of their material. Understanding wood and its characteristics, how it grows, how it reacts and how it is best used, leads to a deeper appreciation of the wood itself.

This book is limited to the trees of North America. The selection of timbers on this continent is vast and varied. It takes years to become really familiar with all the working properties of even a few species. The range of textures and smells, colors and grain patterns is enough to satisfy any purpose. The secret lies in using the right wood for the right reason. Each wood should be explored, used, tested and evaluated. Local woods are relatively cheap, readily available and can be used for a variety of designs. In my opinion, it is far better to use material at hand, and use it well, rather than to import exotic woods with no knowledge of their working properties.

Except for the leaves of poison sumac (Rhus vernix), which cause dermatitis, and perhaps the dust of redwood (Sequoia sempervirens) and red cedar (Juniperus virginiana), which can cause allergic reaction in some people, North American woods are generally considered safe (although dust masks should be worn when exposed to any wood dust). Of the 30 woods listed in this chapter, only a handful are well known to most furniture makers. They are the popular commercial woods and are available at most well-stocked lumberyards and wood wholesalers. The remaining species are not often commercially available. Some don’t grow in sufficient quantities and others don’t grow to sufficient size to be harvested for the mass market. Yet these are marvelous timbers, beautifully colored, with a wide range of uses and working qualities. They, and others like them, are underutilized. What could be more appealing than a custom-made side table, wall cabinet or bench made of sassafras, sycamore or persimmon? If the tree was cut locally, or even on one’s own land, the wood will be all the more special. These underutilized woods should be tried and used. Often they are available for a fraction of the cost of the more popular species.

This section is intended as a reference, a guide to the more common trees that can be easily identified by their shapes, twigs, leaves and bark. For some trees, such as red and white oaks, a more comprehensive manual is recommended to delineate the individual species.

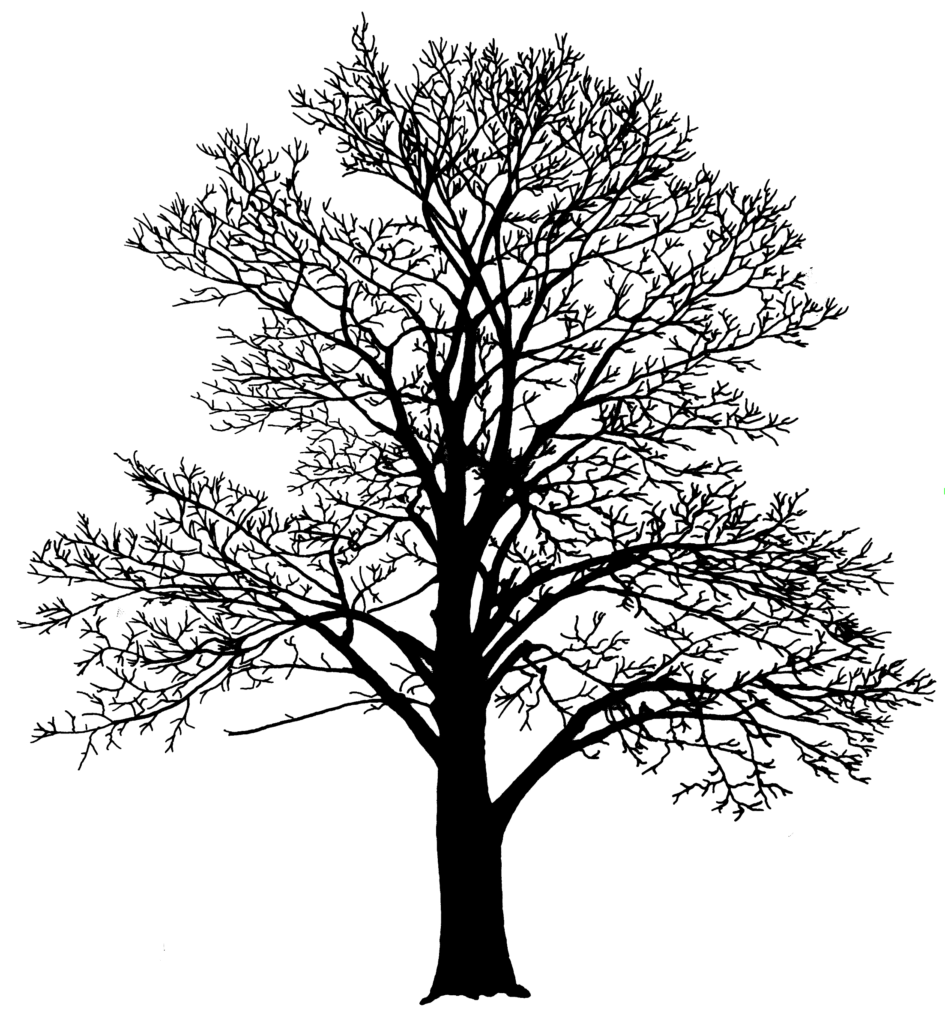

The silhouettes illustrated indicate each tree as an open-grown specimen, field-grown under uncrowded conditions. This basic shape is genetically programmed in the seed. The same tree grown under forest conditions may be quite different; it may have 40′ (12 m) of clear trunk and few spindly branches competing for sunlight in the forest canopy. The forest-grown shape is environmentally induced by shade and the competition from surrounding trees. By using the other characteristics, both shapes should be recognizable as the same species.

The trees are listed by families, in the generally recognized progression from simple to more complex plant structure.

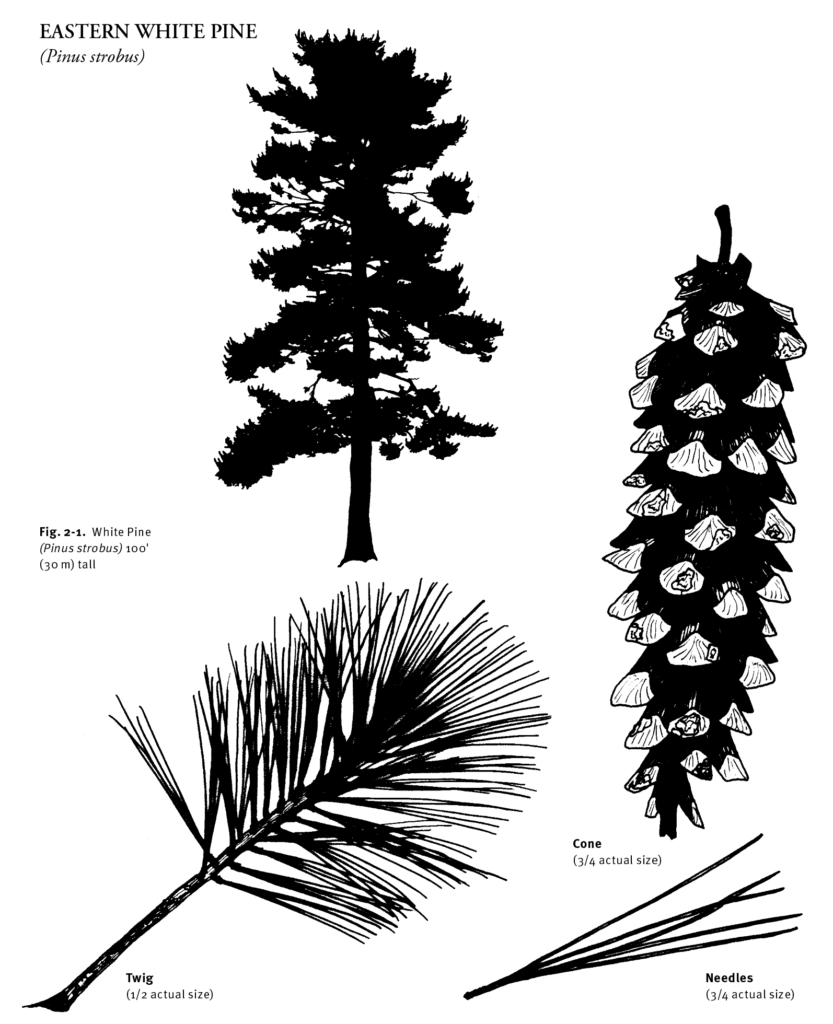

Eastern white pine is also referred to as Northern, soft, balsam or Weymouth pine. The name Pinus refers to the pine family, while strobus means cone. The tree’s natural range is from Newfoundland to Manitoba, south to Wisconsin and Iowa, and east to the Appalachians down to Georgia. Ordinarily it reaches heights of 80′-100′ (24-30 m). Old king’s broad arrow pines, used for masts in the royal navy, sometimes grew to more than 200′ (60 m). White pines can reach 400 years of age.

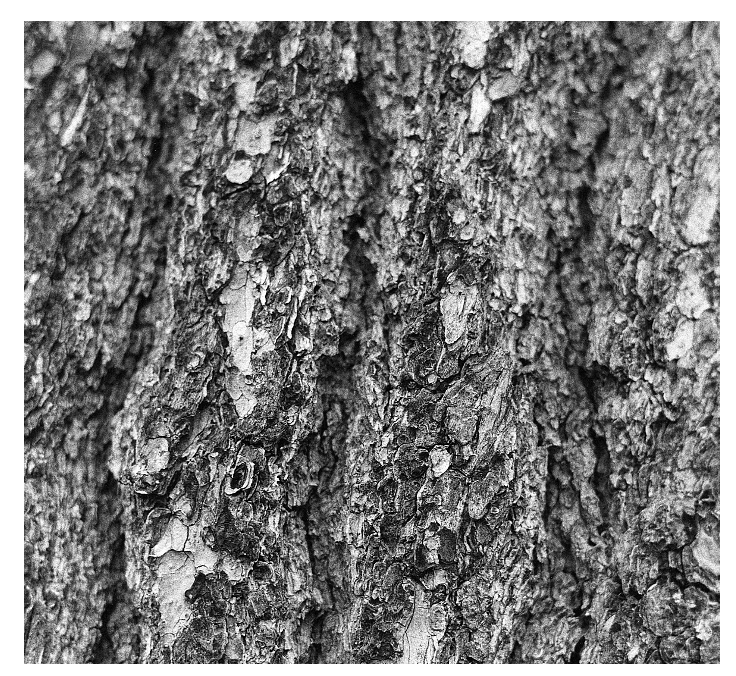

Pines, like most conifers, grow a straight central trunk. The branches of white pine grow almost horizontally, usually in groups of five. The pine shoot borer, an increasing pest in pine-growing areas, kills the leader, forces one of the branches to take over as leader and results in deformed or multiple trunks. Pine needles are 2″-5″ (5-12.5 cm) long, grow in bundles of five, and are surrounded by a papery sheath at the base which drops off after the first season. White pine cones are 4″-8″ (10-20 cm) long, fairly thin, quite flexible and take two years to mature. The bark forms gray scaly ridges.

Courtesy of Univ. of ME School of Forest Resources, A. Autio

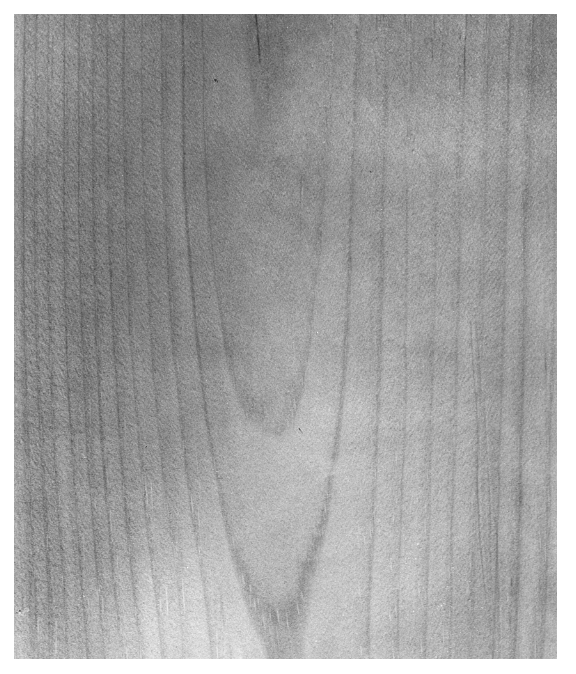

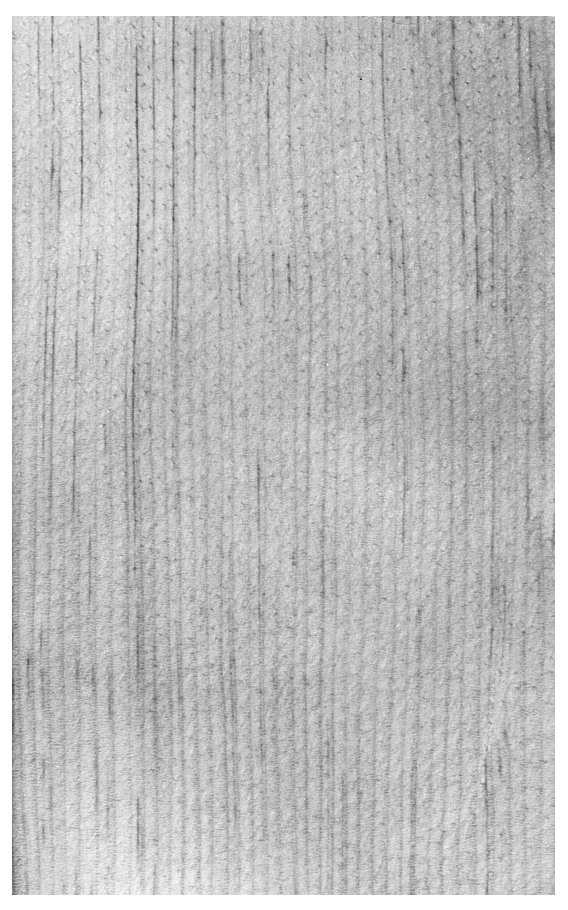

Sapwood of white pine is pale yellow-white. Heartwood is cream to light reddish-brown when freshly sawn, turning to a warm reddish-brown on exposure to air and light. Old, clear heartwood is often referred to as pumpkin pine. The wood contains a fair amount of pitch. It is generally straight, even grained and light, with a density of 25 lb/ft3 (.39 g/cc) at 12 percent MC. It is a real workhorse in most shops, used for jigs, braces and mock-ups. As a pattern wood it has no equal. Quartersawn white pine is the most well behaved of all the native woods. Pine’s ease of sanding, chiseling and planing makes it an ideal secondary wood. When used as such, it fills the entire interior of a chest or cabinet with a clean, woody odor. It is also used as a primary wood. Most of New England’s painted antiques are constructed of white pine. Shellac over the knots prevents the pitch from bleeding through. Perhaps it appears at its best when left raw, or oiled to age naturally.

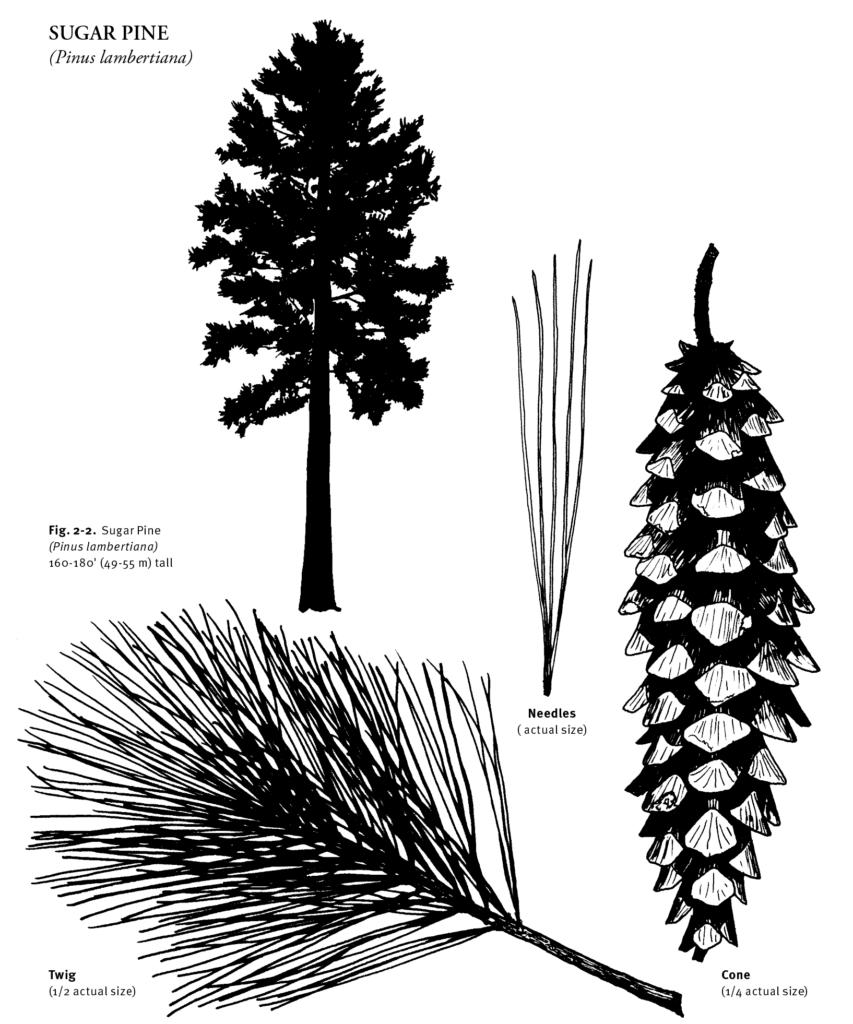

Sugar pine is also known as purple cone pine, or big pine. The Latin name refers to Dr. Aylmer Lambert, a British botanist. Because of its size, it is one of the most prolific producers of timber. The tallest of the pines, it commonly reaches heights of 160′-180′ (48-54 m) and diameters of 4′-7′ (1.2-2.1 m), and lives 300 to 500 years. Its natural range is from Oregon through California. Sugar pines prefer loose, well-drained sandy loams, and grow best in areas having over 40 inches (100 cm) of annual precipitation.

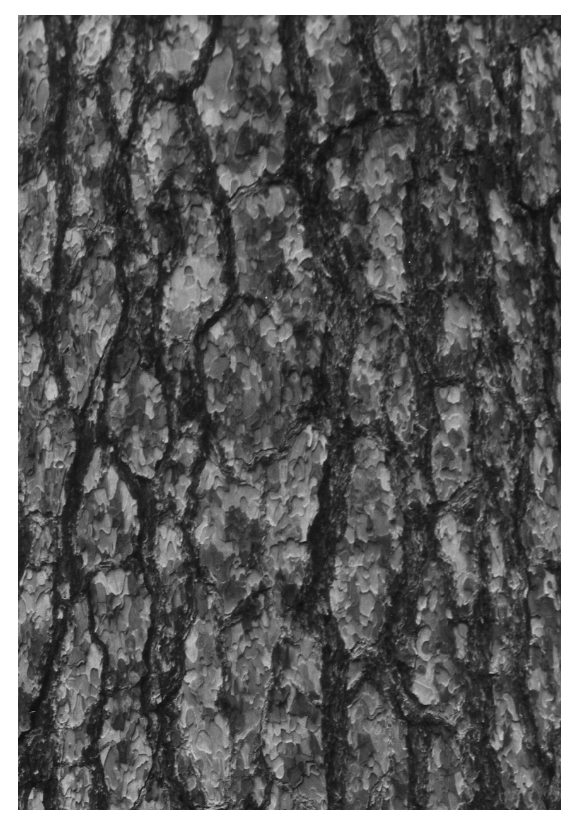

Like the Eastern white pine, sugar pine has five needles per bundle. They are 2-122 – 4 inches (6.3-10 cm) long, bluish-green in color, and remain on the tree for three years. The cones are purplish and erect when immature, shifting to a hanging position as they ripen the second year. They are 12″-20″ (30-50 cm) long, the largest of all pine cones. Sugar pine bark is deeply and irregularly grooved, with scaly, cinnamon-brown ridges.

Courtesy of U.S. Forest Service

Courtesy of Univ. of ME School of Forest Resources, A. Autio

The sapwood is pale, while the heartwood is light beige-yellow, with prominent brown streaks. These are resin canals, filled with crystallized resin. Sugar pine has a distinct sweet odor when cut or sawn. The aged wood does not darken like white pine, but turns light brown. With a density of 25 lb/ft3 (.39 g/cc) at 12 percent MC, the two woods are very similar in working qualities, although sugar pine is slightly coarser. It is used extensively in general millwork for sash, doors and all types of trim and mouldings, as well as foundry patterns, building construction, signs, plywood, crates and even organ pipes. It is not decay-resistant, and should not be used outdoors. The wide, clear widths available make it an ideal cabinet wood.

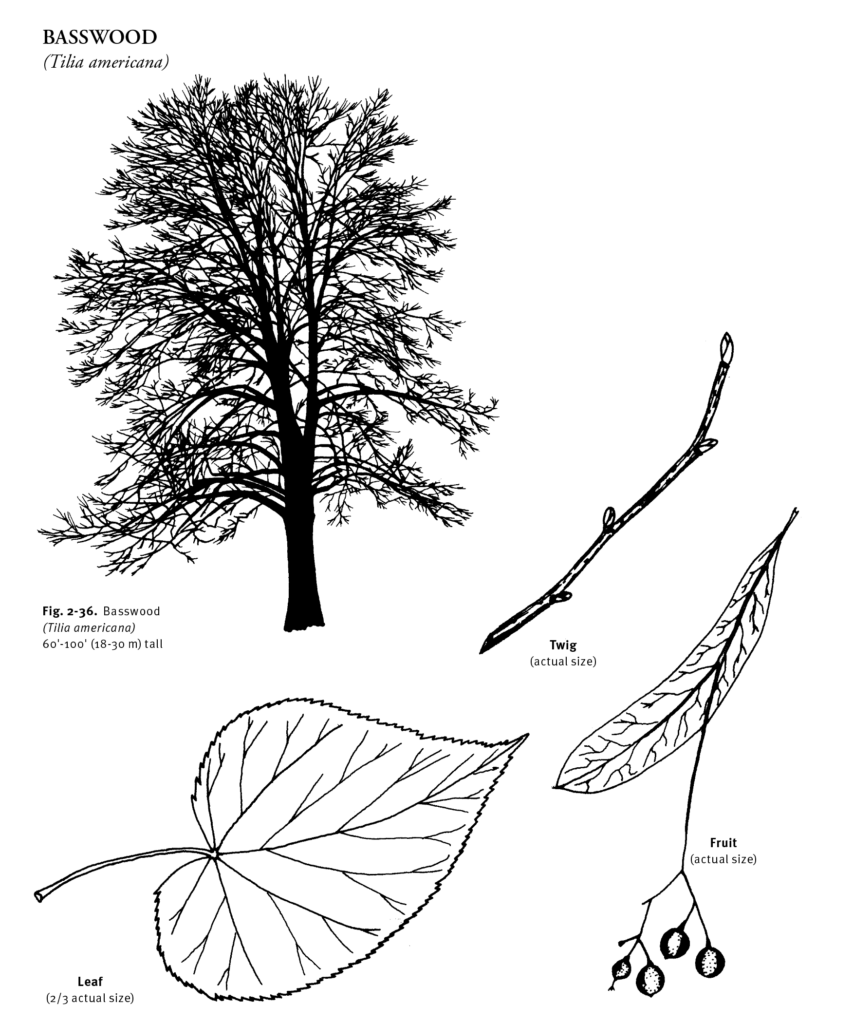

Basswood is also known as whitewood, lime, bee tree or more commonly, American linden, which is a literal translation of its Latin name. It is a tall, 60′-110′ (18-30 m) stately tree, frequently used as an ornamental, and it is well-adapted to city conditions. The species grows best in moist, fertile soil, where it grows rapidly, but only reaches 100-140 years of age. It usually grows with other hardwoods, rarely in pure stands. The natural range is from New Brunswick through southern Canada into Manitoba and South Dakota, south to Kansas and Arkansas and east to North Carolina and Virginia.

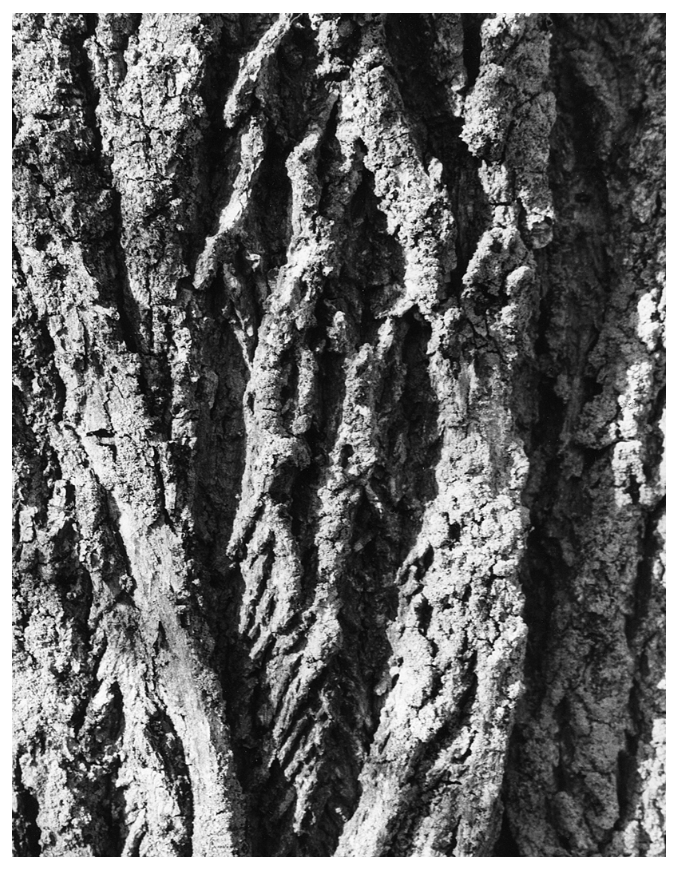

Basswood leaves are asymmetrical, heart-shaped, about 4″ (10 cm) long and 3″ (7.5 cm) wide. The tree is highly prized by beekeepers for its fragrant, creamy white flowers. These hang in clusters attached by a single stalk to a leafy bract. Fruits form as small woody spheres. The bark is dark gray and in older trees is furrowed with flat, scaly ridges.

Courtesy of Univ. of ME School of Forest Resources, A. Autio

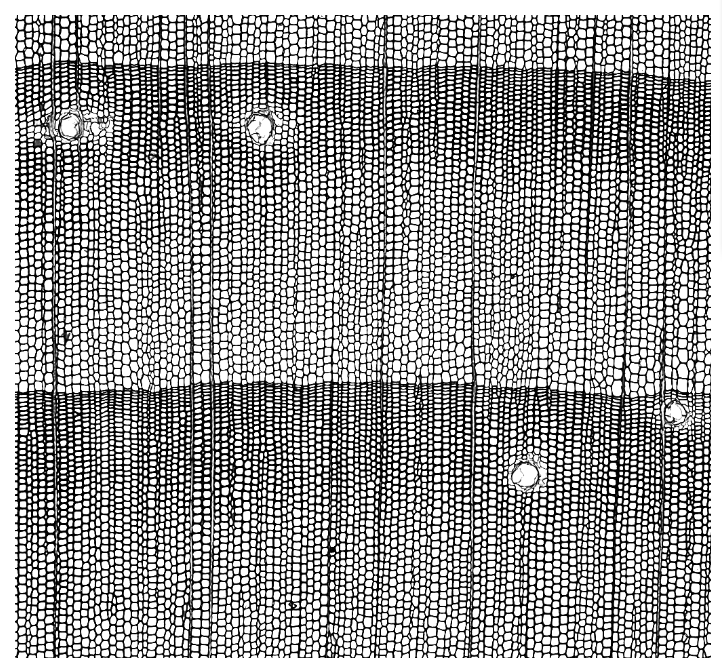

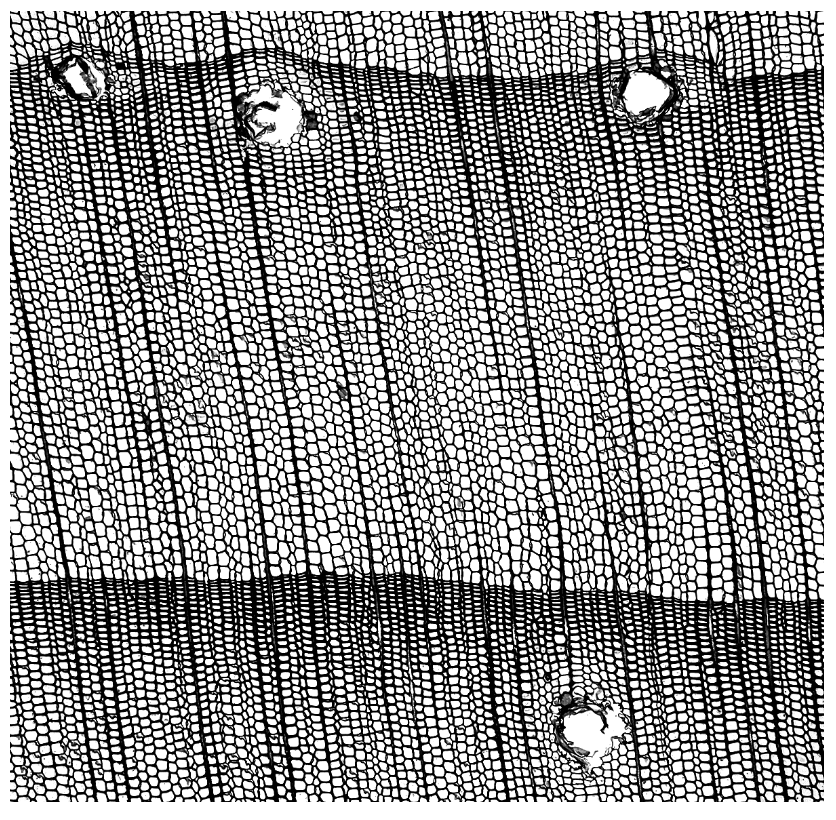

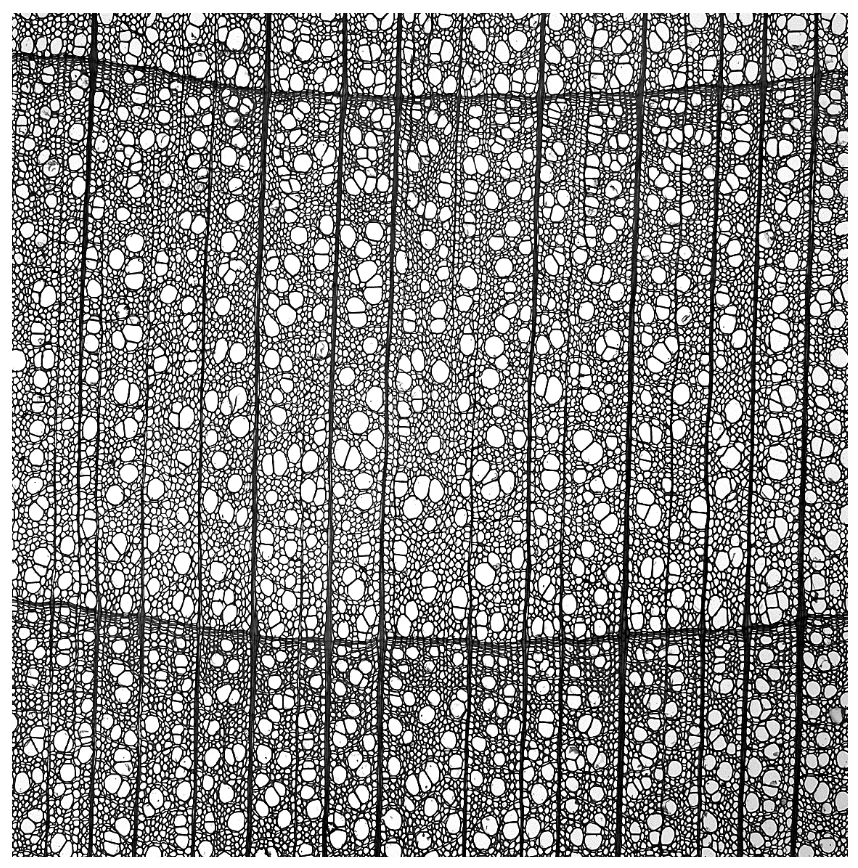

Basswood is very light in color, with almost white sapwood and creamy white to pale brown heartwood. Its weight is also light, having a density of 26 lb/ft3 or .41 g/cc at 12 percent MC. This relative softness makes it easy to indent with a fingernail. It has a very faint odor when freshly cut, no taste, straight grain and virtually no figure. The pores are diffuse and the growth rings are indistinct, with almost no difference in the hardness of early- and late-wood. This softness and even texture makes it an ideal wood for carvers. These characteristics also make it a sought-after wood for tubs, excelsior, slack cooperage, boxes, apiary supplies, venetian blind slats, and assorted wooden ware. Basswood warps and checks very little after drying and is sometime used as a secondary wood in furniture, as well as for plywood and veneer.

Is this supposed to be 2-1/2 – 4? “They are 212 – 4 inches (6.3-10 cm) long”

Today I learned the meaning of “excelsior”. All these years and I had no idea that’s what Bullwinkle was talking about. It makes so much more sense now! https://youtu.be/MDYeav3nQEg

Oops! Yes – 2-1/2″ – I fixed it (thank you!) (It also means “ever upward” – but I’m fairly certain that’s not the usage here!)

I was recently at my friendly local lumber dealer looking for stock to build a six-board chest. This store is really a satellite store for their main lumber yard which is ~2 hours away. I took away some interesting observations from a selection and price standpoint.

Their selection of pine is always disappointing, with only a handful of 4/4 c-select boards ($7.50/bf) and maybe a few more 4/4 d-sel/btr boards ($6.00/bf). The vast majority of pine is furniture grade, however this amounts to maybe 10 FG boards that are mostly 5-6″ wide. I guess they just don’t sell enough pine to keep it at this location. I haven’t really bought wood anywhere else yet, but it seems like these prices for pine are high when you consider they have cherry 4/4 $4.30/bf and 5/4 $4.90.

Poplar had much more stock and better price. 4/4 sel/btr $3.00/bf, 5/4 sel/btr $3.27/bf, and 10″ wide or more for a few extra dimes.

The selection of Linden was even better. Multiple stacks of boards in all thicknesses, even up to 4″ thick. Price was slightly more than poplar (4/4 sel/btr = $3.66/bf, 5/4 sel/btr = $4.30/bf).

4/4 sel/btr for $4.30/bf

I bought poplar this time because they had some nice wide boards, but next time I’m definitely going to dig through the stacks of Linden.

Is this book useful for a European woodworker?

In my opinion, mostly yes.

First, though, in my opinion, no matter its possible usefulness, it is highly interesting, and a great read, so may well be worth getting “just” as a book to read and enjoy.

Furthermore, the chapters that are not straight descriptions of various wood are highly useful to any woodworker, no matter where in the world!

However, I take it you are rather asking whether the information on the various woods are of any practical use to someone who gets their wood from the timber rather than the lumber yard. or even from a houthandel, or a brädgård, or a marchand de bois or …?

Yes, it is. Not fully, because not all the woods described are easily found over here, but quite a few of them are, at least here in the north-western parts of Continental Europe where I am: Eastern White Pine (Pinus strobus), Hard Maple (Acer saccharum), White Ash (Fraxinus americana), Cherry (Prunus serotina), Basswood (Tilia americana), Black Walnut (Juglans nigra), Tuilp Polar (Liriodendron tulipifera) and various Oaks (Quercus spp) are just some of the North American woods I’ve seen for sale over here, several of which I have also bought. For instance, down in my workshop I currently have a nice pile of lovely, quartersawn Eastern White Pine, soon to become an ATC (or, in my case, maybe rather a BTC — Banjoist’s Tool Chest)!

Obviously you don’t find all of them everywhere, and hardly any of them at most big box stores or places geared mainly towards the construction trade. But there is a not insignificant import of North American woods to Europe!

There is of course a risk, when reading the book, of getting enamoured of a wood that just cannot be had locally for love nor money, but then again I believe even in the U.S. there is huge variation in what is readily (or at all) available in different parts of the country?!

And finally, not all places selling wood are very good at labelling their stuff, while the generic trade names frequently encountered are often not very clear.

So, from personal experience and with those caveats, I would certainly recommend this book also to a European woodworker!

Cheers,

Mattias

Thank you Mattias, that is a glowing review!

I’ll have to find a better brädgård somewhere within driving distance where they stock North American woods. Around here (Östergötland, Sweden) there is only Gran (Picea Abies) or very expensive nordic Pine (Pinus Sylvestris) easily available from the big box stores.

You’re welcome, Anders! It is a very good book, is all!

Mind you, there’s nothing wrong with European woods! Beech, Birch, Oak, Sycamore Maple, Pear, Linden, etc. etc., etc. In fact, one of the woods I cannot seem to find where I am (I’m Swedish, too, but live in Belgium), but would love to get my hands on is Sycamore Maple (Acer pseudoplatanus)! I mean, it doesn’t have to be American wood — just ask The Beatles!

I am very lucky, though, in that my local lumberyard (well, almost local; it is two villages/8 km/5 miles away) carries a decent selection of (American) Ash, (European) Oak and (European) Beech, while I am about two and a half hours by car from Arnhem in The Netherlands, where the Arnhemse fijnhouthandel carries more than a hundred species.

You could always try sending an e-mail to one of the teachers in the Woodworking Program at Malmstens and ask if they know of any good sources in Mid-Sweden for furniture quality woods?! I mean, they have to buy their stuff in from somewhere, and most likely have high demands when it comes to selection and quality?!

Otherwise, a while back I happened to stumble across a small place in Stockholm, Pondus Snickeri & Butik whose website at least lists an interesting selection of woods (click through to “Heminredning & möbler” and then select “Massivt trä” in the menu on the left).

Cheers and good wood hunting!

“I mean, it doesn’t have to be American wood — just ask The Beatles!” – Classic comment and great reference….