I don’t need a workbench. I really don’t need to build another French workbench. And I don’t need to spend a week in the Deep South in the middle of summer hoisting thousands of pounds of ancient oak with a bunch of (for the most part) middle-aged, hairy-backed sweaty dudes.

And yet that is exactly what I’ll be doing starting on July 15.

The lovable nutjobs at Benchcrafted have, with some help, put together a bench-building event that made me clear my summer calendar, forsake a family vacation and pony up some serious cash to be involved.

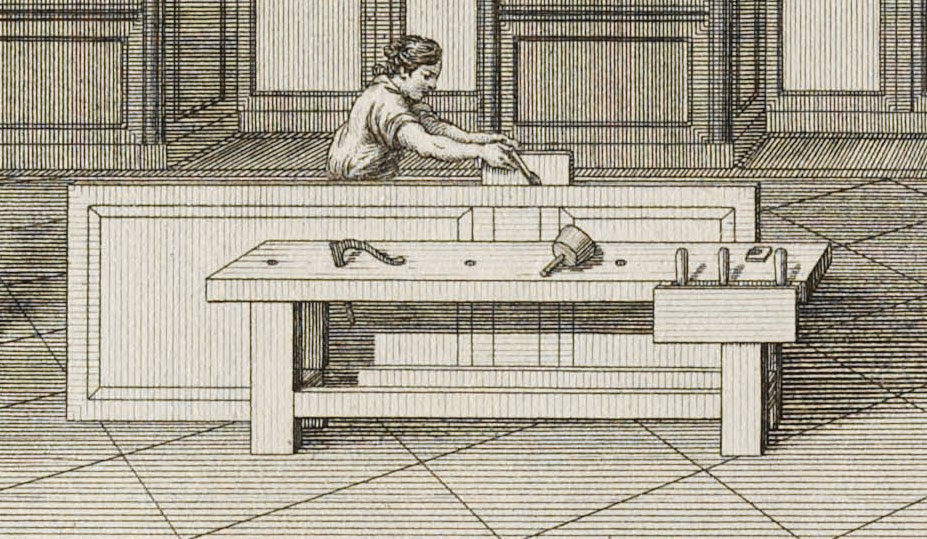

The benches will be massive, built like the simple French versions shown in “L’Art du Menuisier” by A.J. Roubo. The wood is ancient, thick and French. The hardware? Authentic – with metal bits being made by blacksmith Peter Ross. And the machinery we’ll be using to make the benches is big enough to handle it.

I’ll be there to lend a hand with students, talk about the history of workbench design, build a bench for myself and try not to inhale too deeply the inevitable body odor.

All it takes is money. So head on over to the high-IQ sperm bank. Get a paper route. Sell off that bottle of fingernail clippings you’ve been hoarding. This is the bench-building event of the decade – if not a lifetime.

I could prattle on about all the details, but you should instead head over to the Benchcrafted blog page here, see all the photos, read all the text and try like hell to make it.

— Christopher Schwarz

What happens to the bench you build? (that would never fit in my shop).

The better question, Marilyn, is, “What happens to the bench that will be displaced by your new French Oak Roubo?”

Marilyn,

We have benches in the shop, sunroom and den now. And they are in the homes of our friends.

I have a plan for this bench, but I don’t want to commit to the plan until the bench is built.

Give it to Glen. He has an idea of building a bench and could do with a dose of Roubo.

Chris, The smellier it gets, the more authentic 18th century it is!!!

To Make as Au-Naturale as possible.

Maybe I will try to console myself for missing this event by making a bench from railroad ties and then try to convince myself that the end result is just as cool!

Would you take steps (wax ends?) to stop the giant slabs splitting, or would you consider splits part of the character, and just joint it flat each year? I ask because I built an 8″ thick Roubo 2 years ago and the ends are mad split, and i always wonder should i do something about it. It has never got in the way of the function of the bench, except it’s trickier to joint.

Roubo will be turning in his grave at the thought of you using all that horse power 😉

Really?

Given that Roubo expends copious verbiage on the beauty of machines in his furniture-making passages…

Although I am not in regular contact with the dead, I suspect that Roubo would applaud any modern methods used to make this workbench as long as quality was not sacrificed. There are plenty of opportunities to use hand tools when fine tuning the fit of joinery, but only the most saintly would fully embrace the opportunity to hand dimension and surface these boards. Oh yeah, good luck flipping these timbers without the assistance of several able-bodied individuals. Reminds of the time I considered using a four inch thick slab of live oak for a workbench top. Really good deal and a great story about the wood, but I eventually came to my senses. When I hear about French oak, I keep thinking more about wine than workbenches.

So CSchwarz, what is going to happen to the poplar slab drying under your deck?!?! 🙂

No doubt it will also become a bench – in another three or four years.

” – in another three or four years”

Because you want the slab to dry out more or you won’t have time until then?

I have two 5″x12″x9′ slabs of lightly spalted soft maple I plan on using for a Benchcrafted split top roubo. But the slabs were cut from logs, “seasoned” for 3 years, about 5 months ago. Any reason I can’t/shouldn’t start using the lumber in another 5-8 months?

I would gladly sell a kidney to get in on this, but I am 47, (in 23 days) diabetic, and I (probably) drink too much. I don’t think I will find any takers. 🙁

Given the skill of the participants and the provenance of the materials, you should get a good documentary filmmaker to capture the process that week. it could be as fun to watch as the pieces in PBS’s “Craft in America” or others like the ones about Chihuly and his glassblowers.

What a load of crap – what is the earthly point of making an 18th century bench, going so far as to use old, (and authentic French) timbers, even blacksmith-crafted hardware, and then doing all the real work of building it with modern machines?

There is no real answer to this question other than: If you are going to build a bench like this in a week, this is a good way to do it.

Thank you for a straight-forward, unemotional response to my comment. Apparently the word c**p is a diva-trigger for some people. Where I grew up it is the colloquial equivalent to saying “nonsense!.”

What’s with all the biting at Chris’ ankles lately?

So he uses power tools. Big whoop. He’s never advertised himself as being a hand-tool purist. He likes hand-tools, but they’re just tools. He’s always been open about mixing hand and power tools and about using the right tool for the job. I’m sure he wouldn’t want anyone to go deep-sea oil drilling with hand-tools only. That would be silly.

Don’t you think it’s a bit rude to come judge someone on his own blog? Especially if you judge him by “laws” that he never agreed to follow.

Jacques – How ’bout we treat this as a market place of ideas. Chris doesn’t need you to play advocate for him. Try honestly answering my honestly-posed question. By the way, the only rude thing I see here, is your attack on my opinion. Hint: that’s what this comment space is for — it’s not just for sycophants.

“What a load of crap”….

That is the only rude thing I see here.

No I’d say calling the concept a load of crap was pretty rude

just bring the blog to GA (I know we have the interweb here). we will need constant updates and pictures of everyone’s builds. this one i will follow for sure.

Sweet baby Jesus those slabs look amazing! If anyone would have asked me if you could build a bench that way anymore, I’d have said the wood simply doesn’t exist. These will be awesome benches.

No doubt these will be awesome benches. And benches are great and all, but it seems somewhat a shame that such special wood is being used for workbenches and not furniture. Kind of like using elephant ivory and ebony to make a super plow plane. Makes for a cool plane, but maple would have made for a lovely plane too, and the rare and expensive materials could have been put to finer purposes. I’m torn.

I disagree. I think that using this wood for benches is absolutely perfect. It’s old, thick oak. We’re not talking about pretty grain here. But, then again, I would want that plow plane as well, so I’m fairly biased.

I agree with you Adam. I personally would enjoy the bench and the plow plane, easily, as much as a piece of furniture or statue made of the wood or ivory.

I’d sell my wife for a chance to attend this event. But based on current offers, I’d still need $4,499.99 to come up with out of pocket.

With this much woodworking royalty under one roof for this historic build-off, you should get Roy Underhill involved to make a two part special about this for his “The Wood-wright shop” show.

You really need to share the experience of this monster Roubo event with the rest of us, and record it for posterity.

“The Woodwright’s Shop” has always avoided electrically powered machinery (the only violation I recall was Don Weber’s use of trip hammer, and Roy was pretty apologetic about that) and also of filming each episode in a single take. Given that proud 30+ year old tradition, I’m not sure this would be a good fit. But I don’t presume to speak for Mr. Underhill, and I agree that such a special opportunity deserves to be properly and professionally documented. I’ll be following this event with great interest.

I’ve been singing and humming “Georgia on My Mind” (Ray’s version) since I read the BC post.

I’ll have you know that my mason jar full of fingernail clippings is priceless.

Oh well, ebay here it comes.

Sounds too good to be true … maybe in the next life …

Unbelievably cool. Too bad I don’t have the chops… yet. Can’t wait to watch Chris’s video posts for this one. There are so many cool woodworking related people and places tucked into every corner of this world that we’d probably never hear of if it wasn’t for the woodworking community on the internet. Tonight I drink to information technology!

Man If i only had the cash and time. What an experience that will be. Consider yourself lucky just to be a part of it Chris. I wish thats all i can say. HAVE FUN and enjoy the aromas!!!!

8 inch thick top????

BC Blog says the tops should come in at approximately 5 inches. Still, that is THICK.

How about raffling off a seat for $50 a ticket? Would only have to sell 100 tickets to break even. Put me down for one.

Josh

I hear there is a dairy farm nearby where we can all camp. ( Hope it doesn’t rain.) 😉

‘And the machinery we’ll be using to make the benches is big enough to handle it.’

Hmm, is this antique machinery I hope 🙂