Many readers of “The Joiner and Cabinet Maker” are naughty and skip the first project in the book: building a packing box.

The packing box is a fantastic little project because it teaches you some things about handwork that are infrequently discussed, including how to make a square box without shooting the ends of every board before assembly. Oh, and clinching nails.

It is an introduction to mindset of handwork.

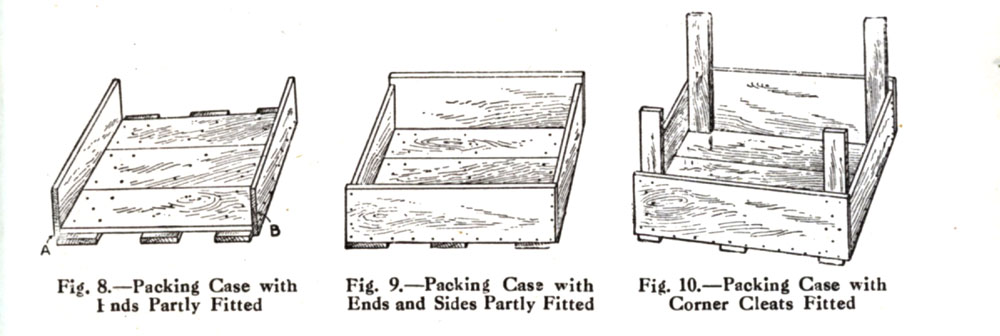

So as punishment for not building the packing box, I am uploading an entire chapter from “The Practical Woodworker, Vol. 1” (Waverly Book Co.) on building boxes and packing crates. It’s interesting reading and discusses the many methods for building things with simple nail joinery that have to withstand rough use. I recommend you look it over before you start making those secret mitered dovetails you’ve been considering.

By the by, “The Practical Woodworker” is a four-volume set of English woodworking books edited by Bernard E. Jones and written by a panel of experts in the field of woodwork. If you ever stumble on some copies for sale, I recommend them over the poorly scanned and printed version from 10 Speed Press, which edited down the four volumes into something less than magnificent.

Download the pdf here and get nailing. Don’t make me sic Megan on you.

Packing Boxes from the Practical Woodworker

— Christopher Schwarz

‘Disobey me.’

‘Some of you have been naughty.’

‘Don’t make me sic Megan on you.’

Very confusing.

🙂

Yes…because it is my sole desire in life that every woodworker builds a proper packing box.

As usual, I have a lot to learn about what women really want.

Shoes are always a good start.

Yikes! 😉

Jones’ ‘Practical Woodworker’ is a fantastic set of volumes, and for once I’m ahead of the game before they all disappear from ebay and the price skyrockets! Do you have that effect in America too? 😉

This was such a large part of Woodworking at the time. Getting good (and eventually speedy) at projects like these would do great things for your productivity as a craftsman. I served a partial apprenticeship as a blacksmith. My first task was drawing out “nail rod” from scrap. Even though I was of the opinion that I was above such things. It taught fire management and hammer control. Did great things for my speed as well. And you end up with some really cool packing containers for your next move. 😉

Some of the boxes that I use to carry tools and small items to job sites were originally Clementine (tangerine) boxes built with ply sides, pine corner posts, and hardboard bottoms, stapled together.

Ponderosa and Jeffrey Pine logs from N. California that were used for fruit packing crates, for as long as the logs lasted, which wasn’t that long!

Fruit Grower’s Supply Company

http://content.cdlib.org/ark:/13030/tf496nb25j/

and

http://content.cdlib.org/ark:/13030/tf929008nm/?query=fruit%20grower%20supply%20&brand=calisphere

I’ll admit to never having built a packing box, but I protest that I spent an awful lot of time as a kid trying to build tree forts, which look an awful lot like big packing boxes from certain angles. I had to learn to drive nails well, because all we had were nails salvaged from old buildings, and we usually had to straighten them out before using them because Dad sure wasn’t going to buy us new nails for these projects.

Some companies can still make decent packing boxes for spare parts, while others definitely can’t.

MgDuff protective zink anodes packing boxes are excellent, built of proper pine boards, reinforced the correct places and look good.

Yesterday I opened a packing box from Caterpillar containing an oil cooler. It was so poorly made It is hard to believe. The material was pressed large wood flakes(I don’t know the real name). It split everywhere, the nails had absolutely no holding power, and generallly a disaster. When you need to ship heavy spare parts around the globe, they should reach the end user in a good and safe condition.

SOme companies still employ people just to make the packing boxes for their equipment, but most of them use some sort of plywood nowadays.

Jonas