This tool began as a question: What the heck is under A.J. Roubo’s workbench?

Right under the benchtop up by the crochet is something that looks like a tool. It looks like it has a couple angled cuts. Because most of the tools shown in this plate show up elsewhere in the engravings in “l’Art du menuisier,” I began poring over the other images in his books.

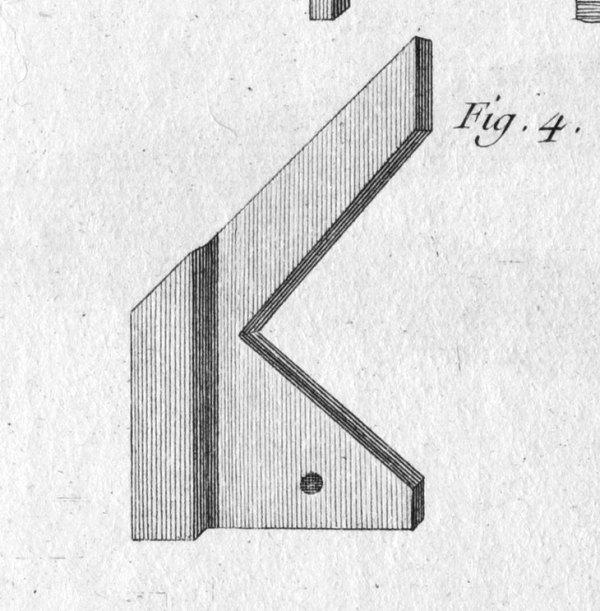

Plate 14’s Fig. 4 wasn’t an exact match, but it had a similar shape to what was under the workbench. After reading up on this square, I became intrigued and decided to make a few and use them at the bench.

The tool looks like a miter square, but it’s far more useful than that. It also marks 90°, and the angled cutout in the blade is fantastic for checking a board’s edges for square.

According to Roubo’s text, this square was usually made in walnut, and it was cut from one piece of wood. This, of course, makes it fragile and subject to wood movement, which would ruin its accuracy. And making all the angles perfect from the get-go is tricky.

So after a bit of thought I decided to use some modern technology to make the square geometrically perfect from the start, make it immune to wood movement, and increase its durability.

The Crucible Bench Square has a blade that is made from 1/4” Baltic birch that is laser cut so it’s dead-nuts accurate. Then it is joined to a maple stock that is machined on a CNC to fit perfectly and make the whole tool accurate. Each square is then hand assembled. It is supplied without a finish, like most wooden bench tools.

It is designed to start square and remain square. And because we know it’s a handy tool, we’ve added a hang hole so you can keep it close under your workbench.

We’ve just finished up the parts for the first 400 squares and they have gone to a shop in neighboring Newport for assembly. In the next few weeks we’ll have them up for sale in our store. My guess is the retail price will be about $27.

Yes, you absolutely could make this square for yourself. And if that’s your inclination, please go right ahead with my blessing. But if you want yours to be perfect (for woodworking) right from the start, our squares will be available.

As always, all our tools are made in the U.S.A.

— Christopher Schwarz

This square looks very useful. Looking forward to its avaliability.

Oddly I was looking at that picture (in Roubo) the other day and wondering what that thing was. Mystery Solved!

Nice! Why not shop-made walnut 3-ply? I’ll send you some well seasoned thin planks and buy back the tools for gifts.

Makes me realize how much trouble I’m having with my try squares trying to see if my boards are truly square. Funny how you put up with issues and you never really think about making it better. Seems like a reasonable price for the time and effort to make one for yourself.

I really like the edge checking feature. Combination squares are a little awkward for that.

Did Roubo build the hang-hole into the design, or did the guy that picked it up at a flea market?

Looks like that image from Plate XIV has a hang hole… or maybe it’s a beauty mark?

I notice on the Roubo original that the stock is cut flush at the 45 degree end of the blade, making it useful for checking something like a table saw blade bevel. The Crucible version has the stock jutting past the 45 degree leg. Is this by design?

Honestly, it made the tool much easier to manufacture. I know it reduces the usefulness in some cases, but it would have added significantly to the price.

I can trim my own when I get it. Easy-peasy.

Dang Chris… I’ve gotta quit giving you my money… 🙂 Excellent idea sir!

Just saw the latest Instagram photos of the tool being prepped for shipment and in it the base handle now appears to be cut flush with the 45º leg? Do I need to get stronger reading glasses or did you change the manufacturing plan?

You are correct. We decided to run all the squares through the saw after assembly to guarantee the 45° and 90°. And that allowed us to clip the corner of the stock and make John Cashman happy, which is all that matters.

Flip it upside down, the other side goes all the way across the blade. But in reality, the blade is going to be too thick to check most saw blade as one of the teeth are bound to hit it. Its hard enough to get a metal blade like on a combi square aligned flat on the saw plate.

Just a question, I don’t really see the problem. If the long blade end is placed on the table, wouldn’t the back of the blade be able to check the 45 degree angle?

It looks like it would be very easy to trim that part of the handle stock off to carry the 45° all the way through.

The relief in the corner is a nice feature. Great tool!

Before it got cold I was trying to make a similar square for myself. Although, it wasn’t Roubo where I saw the picture, and I’m too lazy to run upstairs to thumb through books. Regardless, it appears I had it ‘wrong’. I was trying to make the fat side at 45, and the other side at 60/30 degrees ‘cuz that’s what it looked like in the picture. Figured it was a layout tool for common shop angles.

Thanks for not using red aluminum to make it, which would have sextupled the price.

There is a version that has 60° and 30°. We decided to stick with 45°.

Yea, I’m still wrong. I leafed through my (literal) bookmarks at lunch. Sure enough, the model I used was in the book of plates, #14 as excerpted above. I interpreted it incorrectly. I still plan to perfect my misinterpretation because I want a 45/60/30 layout square at the bench instead of the plastic drafting triangles I currently use. 🙂 Now I can get an inexpensive 45 to go with it, too.

I’m actually excited about this! I love wooden tools. I made the square from the ATC but it is ever so slightly off so I don’t trust it. I have drawer full of squares i don’t trust, so i don’t use them. I saw a picture of this style in one of your recent blogs and hoping you would make this or the batwing style. I’ll be happy to have one i can trust

One question, would it be ok to apply that soft wax/blo from Etsy to this? I like the feel of the finish and feels it provides some protection from the rogue coffee cups on the bench. Or is there a reason these were traditionally left unfinished?

Yup! The squares are sanded nicely and will be ready for finish.

That will be very handy. I also have the same question as John asked above about the stock jutting past the blade and not flush at the 45 like in the original drawing.

looks like it might very useful wrapping layout lines for a tenon shoulder to the next face avoiding the dreaded spiral

cut shoulder

Looks like these have the toasted finish typical of laser cutting, is that correct or is that shadow?

The blades are laser cut. The stock (aka the handle) is machined on CNC.

You could always cut it off yourself.

No pre-release order link?

Nope. We are changing the way we release products to reduce customer service headaches (for us and customers). Most of our customer service queries are “where is my thing?:” and that “thing” is still being made. I’ll write up a blog entry explaining it soon. But as soon as they are done, we’ll start selling.

Could this also be used to square a Festool track saw guide against the workpiece? I see them for sale for lots more money!

I don’t see why not, you can do the same thing with a speed square or combination square. Biggest difference between that and what you’re talking about is a way to register the square to the t-track slot. A couple carefully laid out and drilled holes could do that, or better yet make one that you can true to the track saw and buy a LAP one for your general layout work.

Could the changing of the angle from changes in humidity have been used in some clever way in an old time-y climate-uncontrolled workshop? Aside from knowing your angles would be perfect at whatever moisture content you made the square at, assuming equilibrium of all the wood in your shop… I couldn’t imagine anything, but perhaps that is only a statement about my imagination.

Oh, typing that has just made me think of another thing – you could show it to your square to check humidity over time. Maybe that could inform how you shaped things knowing they would later go into a heated house.

Nice! I see it also useful to mark centre of square stock to get ready for turning.

How about offering a Steel (Stainless?) version for a higher price? the problem with any wooden marking tool is that the knife you use tends to eventually ruin the edge…. and square and straight is no more.

OK for a pencil, not so much for a marking knife.

The advantage is that all the programming for the CNC machines is done. All that needs doing is to change the material and the speed of machining.

As an aside, I assume you are using some form of thin Baltic style plywood. You use Bamboo plywood on your set of curves. Why did you not use that material?

Having said that, I am looking forward to owning one myself……

I’ve been wondering about “squares” like these also. I’m sure you’ve noticed they show up in several texts, and with several angles… what are the ones for that have no right angles?

This is an educated guesstimate but my suspicion is whoever made the non-90° was regularly building something that used the odd angle. I mean why do we use squares? We want to check and lay out the most commonly used angle quickly.

You (Chris et al.) might be interested in this listing on etsy: https://www.etsy.com/listing/772080060/ensamble-of-vintage-french-hand-tools?ga_order=most_relevant&ga_search_type=vintage&ga_view_type=gallery&ga_search_query=carving+tool&ref=sr_gallery-17-9&organic_search_click=1

There is a square very much like the crucible square.