I don’t keep a diary, I just look back at Instagram to see what I was doing on any given day. This is how I know The Chairpanzee was born on 11th April, as nothing more than an idea in search of a good name. That day, in the early stages of my COVID-19 infection, I sat at my desk designing a new low back chair. I used other chairs I admire as a reference point, noting their rake and splay angles to understand the visual effect they generate. Rake and splay are all very well on a drawing, but when it comes to making a chair what we really need are a sightline and a resultant angle for the legs. This approach allows us to drill with reference to a single sliding bevel (set to the resultant) which is positioned along the sightline. It struck me that a simple device to tell us those sightline and resultant angles based on any given rake and splay would be a useful tool to own, which brings us to today.

There are published tables available to use as a reference, but for this product I went back to first principles, enlisting my older brother (an Engineering Ph.D.) to do the hard bit. Shortly after, armed with lines of data, the first prototype was born. An important concept from the beginning was to return both the sightline and resultant for a single setting of rake and splay, which led to the double-sided design. Every good product needs a memorable name and, having christened an earlier product the Bevel Monkey, it seemed only right to continue the simian DNA line. My son George eventually won the pun-off on a family walk, coming up with the perfect name: Chairpanzee.

Collaboration is a key aspect of product development; it leads to ideas being challenged and ultimately creates a better end product. A good idea is also worth nothing without a route to market, so with both of those principles in mind, Chris Schwarz and I formed an alliance to develop a product that would become part of the Crucible range. We pulled apart the flaws in the first prototype, which was too big and suffered from racking sliders that jammed. We also needed to scratch an itch that Chris had: the thought that a wheel-type gauge might fit the bill. We got to a wheel gauge eventually and I still have a fondness for its Fibonacci-like pattern of holes, but it would have been too big and too expensive to produce. You have to be willing to drown a few ideas in the river on this journey.

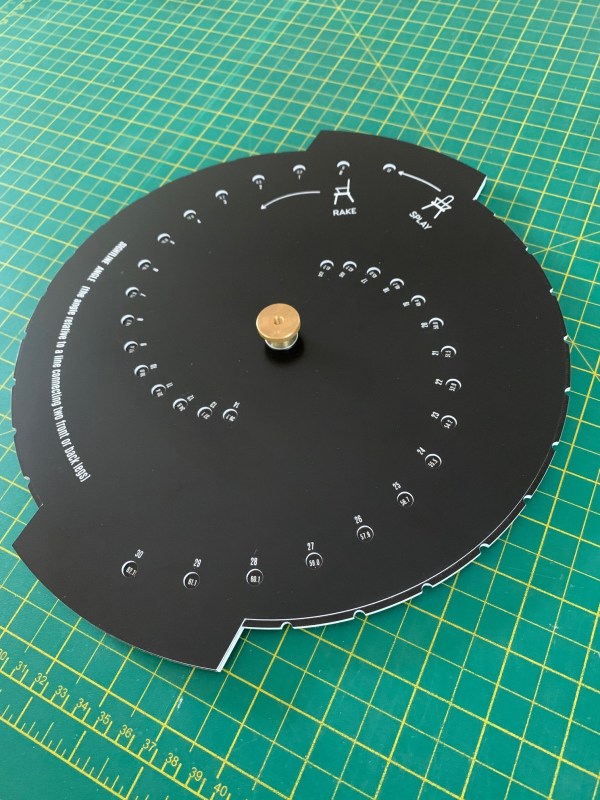

By prototype three we were zeroing in on the concept of a double-sided slider, which could be produced to a high quality at an affordable price. We made an important step toward a printed product, which allowed us to reproduce detailed graphics and fine data on a durable surface. Laser engraving had been a useful development tool, but ultimately too costly as a production solution. Following creation of the graphics and layout, we arrived at the end of the story with prototype number four, which looks exactly like the product you’ll be able to have in your hands very soon (pictured at the top of this blog entry).

— Ed Sutton, FirstLightWorks

I’ve been waiting for this one, Ed. Congrats! Looking forward to trying it out!

Looks like chairmaking for monkeys.

On the picture of the fourth prototype (at the top of the blog entry), it looks like the rake and splay are the angles between the legs rather than the angles between each leg and a line perpendicular to the bottom of the seat. Is that correct?

The designations of “rake” and “splay” on the illustration are a reminder that “splay” is shown in the elevation view and “rake” is shown in the profile view. A full explanation of the angle (the supplement of the angle off of a true vertical line) would not fit on illustration.

Also, some basic knowledge of how rake and splay works (which is what you have just exhibited in your comment) is assumed when you whip out a Chairpanzee.

Thanks.

A precision of a tenth of a degree! Is this for people using CNC?

Sylvain

We will offer a version where a chimpanzee has used WhiteOut to redact the tenths. It will cost an additional $100 to pay the chimp (we are not monsters).

Personally, I use the tenths because it is easy to set a sliding bevel to something near a tenth of a degree. And a degree makes a visible difference in a chair leg that is 19″ long – even more so with a table leg that is 30″+ long.

However, feel free to save the $100 and WhiteOut the tenths.

Or round up/down as appropriate.

I assume you’ll be using a blonde chimpanzee to white out the computer screen before sending to the printer?

Fascinating. It can’t be a coincidence that this was posted on the same day as a research paper on compact nuclear fusion.

Nice! Looks quite like the “settings/embroidery/knitting calculator” of my old sewing machine (a Pfaff from late 60s). Quality of lamination is critical here.

We are working with a company that has made these for more than 60 years. Their quality is excellent.

Does it come with complimentary soft fruits?

No. But if you’re dissatisfied with the product you are allowed to throw your feces at passers-by.

On the top photo, I don’t see a calculation of the resultant angle. Is it on the back side?

The flipside of the Chairpanzee has the resultant calculator. After you set the splay angle on the sightline side, you flip the Chairpanzee over and the calculation carries over to the other side, giving you the resultant without changing the position of the slider.

Chairpanzees are clever animals.

Looking forward to monkeying around with this. The resulting chair could have legs any which way but loose.

Nooooo! Must. Have. Wheel. Gauge.

Wait, wait, you’re going to sell us what? A spreadsheet? Okay, cuz I’m already non compos mentis, how much? Sixty years ago I took a freshman Engineering Graphics course where they taught us to make nomographs. [A graph consisting of three coplanar curves, each curve graduated for a different variable so that a straight line cutting all three curves intersects the related values of each variable.] Is this it again? https://en.wikipedia.org/wiki/Nomogram

I started out thinking about addition of unit vectors but remembered a large part of woodworking is learning tricks to avoid doing any actual math.

Looks an awful lot like the thing my teachers used to figure my grades out on back in junior high

Curious if any of the resultant angles are recommended for short or long legs on the chair or table. Can’t wrap my brain around what looks best proportionately. George Walker? Jim Tolpin? Seems this device may tell a calculated angle, but not what looks best?

I build half-scale models with wire hangers as the legs. I bend them until they look right. Then I can measure rake/splay. Or i can jump to sightline/resultant.

Models work with short legs and long.

So it’s possible to chose a rake and splay, your chairmonkey will determine the resultant angle and the chair might still look wrong? Isn’t there some kind of “Golden Rule” that would be based on the seats size and the height? Apparently the chairmonkey doesn’t help design the chair but only aids in the construction, good or bad.

Just like a board foot calculator, the Chairpanzee cannot help you with beauty/awkwardness.

When I teach this process with half-scale models, students immediately spot awkwardness. You (and most people) have seen enough chairs to know what looks stable and good.

There are books on chair design (Jeff Miller has a good one). But the best education is to look at chairs.

Did you consider or using a slide rule as a model for this? It looks like you are close to one with the design you already have. You may be able to show all the scales on one side with that approach. I have some amount of nostalgia for slide rules.