This week I’m building two prototypes for a lowback stick chair for my next book. There’s a good chance this form will be a failure. But if I don’t try, then it definitely will be a failure.

Chair prototypes start with sketches and hours of staring at the hundreds of images I’ve collected from my travels, auction sales and images shared by brother and sister chair nerds.

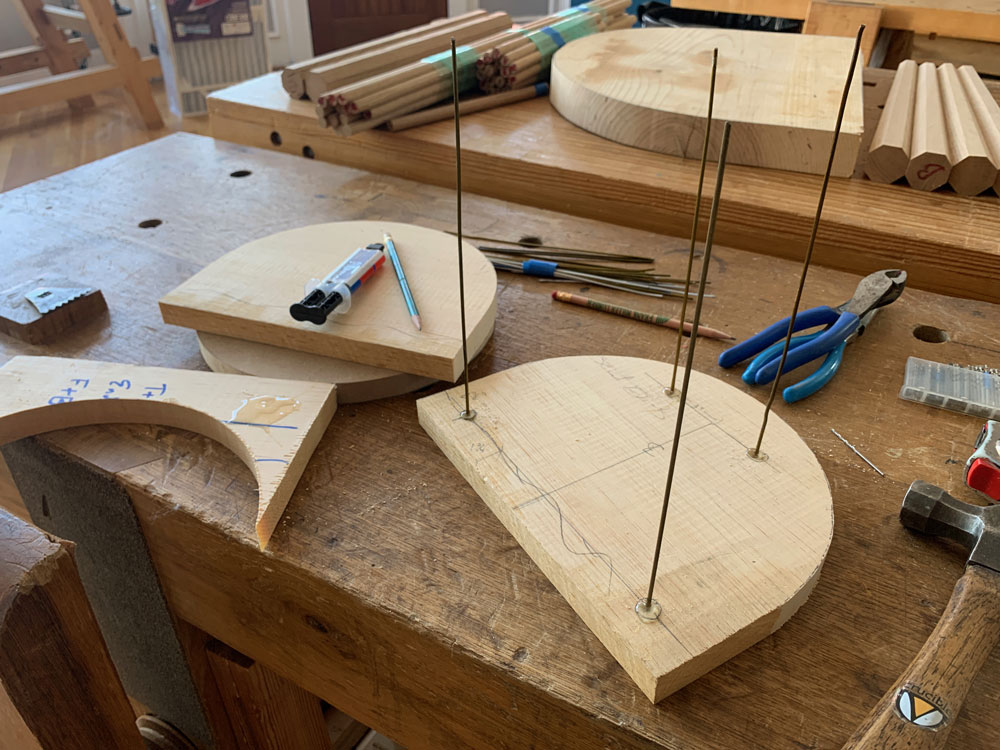

Then I build a half-scale prototype with scrap wood, wire hangers and epoxy. I’m starting with a basic D-shaped seat, though that might change down the evolutionary path.

For this prototype, I found a better way to glue the wire hangers into the seat. In the before times, I would drill a slightly undersized hole, coat the end of the hanger with epoxy and tap it in. Then I’d dab some epoxy around the place where the hanger met the seat.

This was usually a strong-enough joint to bend the legs a few times. But sometimes the leg would come loose while bending it.

To fix that, I first drilled the hole for the hanger and followed that with a countersink. This created a bowl for the epoxy to pool. This greatly strengthened the joint, and I didn’t have to be gentle while bending the legs with pliers.

After settling on the rake and splay for the prototype, I visit my “boneyard” of chair parts. These are the bits I’ve accumulated after years of building chairs for customers and in classes.

Using leftover parts saves time, of course. But it also helps me visualize what’s right and wrong about a prototype. By using old legs at new angles, I can see clearly if I like the rake and splay without being distracted by a new leg shape.

Put another way: If I build a prototype with a new leg shape, new leg size, new stretcher orientation and new rake and splay, then it’s difficult to decide how to improve the chair. Is it the angles that are wrong? The leg shape? A combination of two factors?

It’s a cautious and slow approach, but I rarely hit a dead end as a result.

The other nice thing about this approach is that even a failed prototype isn’t a total loss. I can cut up the cherry, ash and oak parts and put them in my smoker with a pork shoulder and prototype me some pulled pork sandwiches.

— Christopher Schwarz

That’s the only thing I don’t like about my pellet smoker, I can’t recycle my hickory and cherry scraps…but otherwise I’m a pellet smoker convert

My whole life I grilled with three types of wood; live oak, pecan and mesquite. I actually googled if you can smoke meat with red oak when I started wood working. I honestly didn’t know.

Oak I knew. It was him using ash that grabbed my attention… That was a new one on me.

I’ve been mostly using hickory, cherry, and apple… made some bodacious brisket the other day. Yum.

Do you ever combine boneyard parts to build a finished chair, or are spare parts only good for prototypes, and lunch?

If the chair is going to be painted, then yes. I’ll use boneyard parts in a commercial job.

If the chair is going to have a clear finish, there’s little chance that will work. I strive to get all the parts for a chair from one tree so the color matches. White oak can look anywhere from deep brown to grey. And boy is it ugly to have five different colors of oak in a chair.

“What wood is that?” “White oak”. And what wood is that?” “White oak”. “They are different “ “Yeah, I know, they are white oak”. Okay.. well, what is that wood ?“ “ Ahh,white oak darling “

“You just earned a night on the sofa”

I likes me some pulled pork sandwiches. I am just finishing up 2 stick chairs out of cherry and I do have some scarps of wood that I may have to use to smoke me some butt

pulled pork sandwiches – yumm

Why not try some good hot melt glue (such as the Gorilla brand, which is high strength, interior/exterior)?

I don’t have a glue gun. I always have epoxy. But I am sure your idea is a good one!

Its the epoxy that makes the sandwiches rib stickin good.

Do you use an epoxy gun? Or just mix up the 2 parts and pack it into the divot? I bought one of those guns for doing my staircase, i really like that no drip epoxy but I have to order the refills on amazon

I don’t use enough epoxy to justify a gun. I just use the little packs from the hardware store.

As an engineer it was drummed into me don’t change more than one variable when trying out things. I guess this holds true for woodworking

Peter

If this adaptation prototype leg fixing isn’t enough, has anyone already suggested drilling all the way through and clinching? The wire leg should break before it comes out.

Can’t remember if this has been brought up before for the wire legs, but if you drill through and clinch the wire then the wire should break from metal fatigue before it pulls loose.

A note on today’s tribble pic: glad to know im not the only member of the biennial instant weight loss club.

Looking forward to see what you are going to come up with.

Joan Crawford: “No wire hangers, ever!”

Have you ever tried hot glue instead of epoxy? If it comes loose you could just hit it with a heat gun and your back in business. I have also heard there are high strength hot melt glues intended to be used as permanent bonds.

I’m afraid not. I don’t have a glue gun.

Super glue “gel” works good too!