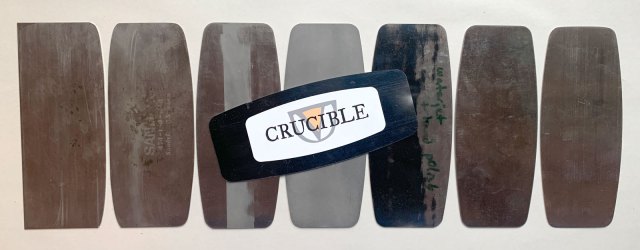

My January column at Core77 is available to read for free and covers the design process we went through to develop the Crucible curved card scraper.

It’s a simple tool, but it’s remarkable how much work goes into something before you make several thousand of them. This article covers everything from the historical research to the pricing. Some of you might enjoy seeing how the sausage is made. Some might not.

Thanks as always to Core77 for giving me wide latitude about the topics I cover. And thank you for reading it.

— Christopher Schwarz

P.S. You can read all my Core77 columns via this link.

I picked up one when they first came out. It is my go to scarper. It works great for removing finishes ( most over 100 years old but under 5 or more coat of paint) when working a custom piece of furniture it will do the job it was designed to do and the best part is, my thumbs love it. I can sharpen it fast and easy and it holds and edge quit well. Thanks for all your work on this tool. I love it.

Thanks Rachel. My thumbs agree with your thumbs!

Interesting read. I had one of them on my Christmas list, but my secret santa didn’t get it, so have to buy one myself. Any chance the curve would be good for setting the camber on a jack plane iron? Or maybe V2 could have a short side with that radius?

As a former tool designer I did enjoy reading about the process of developing tools and it awoke the engineer in me, which prompted a question. Have you considered using a shear die to form the primary shape of the scraper as apposed to using a water jet? It could offer a reduction in you production cost. Either way great story and thanks for sharing.

Yes, we had. The die is a big upfront cost. We’ll probably be able to justify it someday.

After I read your column I vaguely remembered that I had a scrapper like this. Sure enough, I dug around the shop and found it. It was part of a set made by Thomas Finn – PAX tools in England that I had bought a long time ago (perhaps in the 1990’s). Looked up their web site and they still sell the set https://www.flinn-garlick-saws.co.uk/acatalog/Pax-Shaped-Cabinet-Scraper-Set-33.html#SID=528 I guess I should give it a try and see if I like it.

Are you sure it came with the double curved scraper? The link suggests it is *NEW*. Also you can find the 3 piece sets elsewhere (like Tools for working wood). I am guessing it is a new addition inspired by Crucible’s.

Yes, I saw that. I’m sure I bought it as a set a long time ago. I also found the other three cards in the set. I bought it locally at one of the three woodworking stores here in Portland.

I bought almost the same set on Lee Valley about five years ago, so it’s not really “new”, and it certainly isn’t “inspired by Crucible’s’.

Here is the link:

https://www.leevalley.com/en-us/shop/tools/hand-tools/scrapers/32639-super-hard-curved-scraper-sets

Here is what LV says about this scraper (and the reason I bought it at the time):

“The third style has two different gentle cambers that are perfect for stripping glue lines or flat work, or for localized scraping when you want a precise, controlled action without using a lot of thumb pressure (which can reduce sensitivity).”

Another great piece at Core77. Especially love the reference to Chomsky/Herman. Didn’t want the one cranky comment over there to be the only comment but since I can’t make that “comment” button work I will post here.

Thanks for sharing the design process. And yes, we have all see curved scrapers for curved work, but nowhere had I ever seen a curved scraper for flat work. Indeed, it used to be Hell on one’s hands to do the work while keeping the scraper bowed. The Crucible scraper has worked beautifully for me and, given all the knowledge that came with it, the scraper is a smoking deal at 20 bucks.

Totally agree with your comments.

I think that troll’s comment was insane because he basically asked Chris to do the work that the article specifically outlines they did! And the charge that people should just make the thing… the article explains they shared instructions on how to make your own for free. Read the article before you comment!!!

As for the actual scraper? Well worth the $20. I honestly didn’t know how a good card scraper was supposed to perform until I got this one. Yeah, I paid $20 for something I could’ve theoretically made for a few bucks and some time. But I am not an old professional that has the experience and intuition to fire up the grinder and do this trivially! So I got a great tool that I worked wood with *immediately*, and for that $20 I also learned how a good scraper should work so that in the future I can better maintain this scraper and any others.

You should get Wilker do’s to do a Crucible spot on one of her videos. It’s not like an advertisement… its more like your best friend telling you about a super cool, new tool they just found. Very effective.

He’d have to attach a motor to it.

I like watching how sausages are made and now I know how this scraper was created. What I don’t know is how to use and what tasks the scraper is best at. How about a blog entry to help us new wood worker become aquatinted with the “Scraper”.

Enjoyed the article and I love this shape for a scraper. I used the pattern you posted a while back to make my own. Not because $20 was too much, but because you were out of stock when I needed it. Heck, at $20, it still would be about the least expensive item in the tool chest (aside from a pencil).

I’m sure others have tried this, but I’ve found the easiest way to sharpen it is with my three piece “EZE-Lap” diamond hones. Used like a file they give a great surface and I find it easier than trying to use my stones.

The scraper works great- love mine. Haven’t seen the words ‘rooting’ and toolchest in the same article before- well done!

Have read the comments over at Core77; there are some hateful people in our hobby/trade/craft. Well to show them I just placed my order for a scraper… HA!!!

I remember scrapers much like this from my woodworking classes in grade and highschool more than thirty years ago. They had sharp corners, not rounded, but the curved working edges were just the same, as far as I can recall. Look at the third one at https://www.dictum.com/en/scraper-blades-jbd/scrapers-4-piece-set-thickness-08-mm-703536 for an example.