This is an excerpt from “The Woodworker: The Charles H. Hayward Years: Volume II” published by Lost Art Press.

The practical working of wood is largely based upon an extraordinarily simple fact; a fact which every man who goes in for woodwork, even in an elementary way, soon comes to discover for himself. This is that it is easier to take a tool right through than to stop it short—at any rate so far as hand tools are concerned. Men in the past found this out at a very early period, and traditional methods of construction have been based on and developed around this simple truth, but it is rediscovered daily by every man who picks up saw, plane, file, and so on.

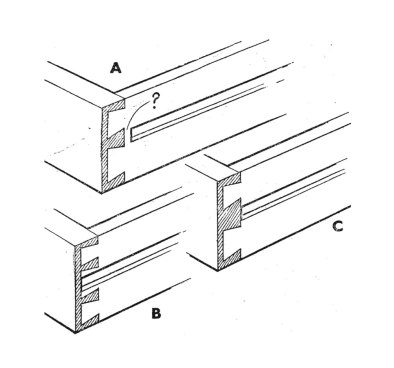

Consider the number of times you experience this; how much easier it is to work a through groove than a stopped one; how simple it is to take a saw right across a piece of wood, but what a different proposition when it has to be stopped short as when sawing the sides of a stopped groove; how straightforward it is to plane an edge straight, yet what a nuisance it becomes when it is stopped at one (or both) ends and you cannot use the plane except at the middle (haven’t you been tempted to plane the edge straight and plant on the stops afterwards!); how a simple chamfer can be formed with the plane in a few seconds, but takes probably ten times as long when it is stopped; and so the list might be continued. These points are brought out in Fig. 1.

Of course, it does not follow from this that grooves are never stopped or that chamfers always go right through. Sometimes you cannot help yourself; possibly the one may be a constructional necessity, or the other so attractive a feature that it is worth the trouble involved. But there is no point in work for its own sake; it is much better to go about things in a simple way, especially when the involved method carries with it no corresponding advantage.

It is because of this that it is generally easy to tell whether a design is the work of a practical man; or, to take another aspect of the same thing, why a design by an artist invariably requires the cooperation of an experienced woodworker to convert it into terms of practical working. A simple example came to our notice recently. The sides of a drawer had to be grooved to fit suspension runners attached to the cabinet sides. They were shown stopped at the front as at A, Fig. 2. Surely no practical man would ever have given such a detail to be worked by hand when it would have been just as easy to arrange things as at C in which the plough could be taken right through before assembling the drawer. In fact the arrangement at B could have been followed, so enabling the runner to afford support almost to the extreme front.

This running-through business is of particular interest because it is largely peculiar to wood, and it is partly due to wood being a natural material which must be used in the form in which it is found (we are ignoring here made-up materials such as laminboard, plywood, etc.). Some materials (metal, plastics, etc.) can be cast or moulded, and projections and stops present no more difficulty than flat surfaces. With timber you fell the tree, convert the log, and then think in terms of so many straight pieces of material. Another point affecting the thing is that wood is comparatively soft so that you can set a metal cutter in a stock (that is, make a plane) and take off shavings, the device having the advantage of helping to make the work straight and true. But of course you have to be able to take the tool through without hindrance.

Perhaps a better appreciation of this point is to compare it with the method used by the stone mason. You cannot use a plane on stone; you have to chip it away with chisel and hammer. There is therefore no point in running through. If a mason has to work a moulding around, say, a window opening, he does not form the joint right at the mitre. Instead he carves a special corner stone as in Fig. 3, this having the two joining mouldings carved in it. Thus we see how a fundamental difference in methods of working has evolved a technique peculiar to the material, this basically affecting the design.

This brings us to an interesting point. The carver in wood uses tools and methods of working which are similar to those of the sculptor in stone. He uses gouges and chisels as distinct from the planes and ploughs of the joiner or cabinet maker. Consequently the running-through idea does not apply to him. When therefore a wood carver makes a piece of woodwork he often carves it in the solid rather than joins pieces together, and the mitres of his mouldings are like those of the mason. In fact, the same idea is occasionally carried out in joinery in which a timber framing is used. In Fig. 4, for instance, the joint in the moulding is not on the mitre line, but runs straight across in line with the shoulder of the joint. Clearly the moulding plane could not be used on the uprights, and the corner would have to be cut by the carver. This joint is, in fact, known as the mason’s mitre, and the corresponding joiner’s mitre is given in Fig. 5.

It is an interesting thought that if the technique of woodwork had developed through the wood carver rather than the joiner, the mason’s mitre would probably have become the rule rather than the exception.

— MB