This is an excerpt from “Mouldings in Practice” by Matthew Sheldon Bickford.

A table saw has a fence, a powered jointer has a table, your bench has dogs or a stop. Like any other task in our craft, bracing a piece while working is necessary. The solution is not always obvious. A sticking board is the appliance you will make to hold your work as you create profiles using your planes.

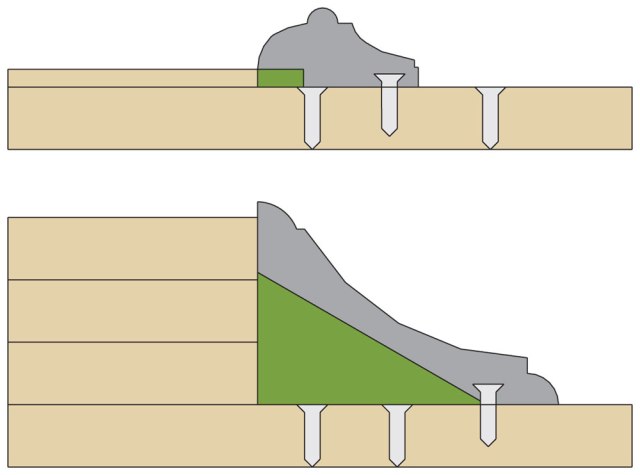

A sticking board in its simplest form is a base, a backer board and a stop. I use 1/2″-thick MDF (medium-density fiberboard) with screws set in a few inches from the end for the stops.

I add screws on both ends of the sticking board for the times when I need to plane in the opposite direction so the board’s grain runs in my favor. I make the sticking board wide enough so that it can be pinched between the dogs on my workbench and puts the work near the front edge of my bench.

Most of the force you exert upon the piece with these planes will not simply be downward against your bench. The piece you are working is often angled, so the planes are held at an angle, too. Simply clamping a piece between two bench dogs is not ideal for several reasons. This is one of those reasons.

A sticking board gives you a backboard to press against and resists this lateral pressure. The sticking board can be clamped in your bench between dogs and/or held down with holdfasts, screws or numerous other solutions. A firmly held sticking board prevents the workpiece from snapping out of the dogs and you from doing a belly flop across your bench and damaging the plane, iron and the moulding being stuck on your bench.

The sticking board will also prevent the clamping pressure of the two dogs from distorting a thin moulding.

Because the piece being worked upon is not usually pinned in the sticking board, gauging your progress does not require you to bend down and look for gauge lines, leftover rabbets or at spots in less-than-ideal light. Simply pick the piece up, rotate it and examine it.

As a moulding becomes more intricate, so does the sticking board. The rabbet for a picture in a frame is cut first, making it more difficult to work from that point. Attaching a perfectly dimensioned piece to the board can make a non-square piece sit square again.

The options for specialized sticking board design are too many to list. Change the board to fit the piece.

Finally, a sticking board, if rigid enough, can turn a typical 7′-long workbench into something more than 8′ long. I even have a game plan for the time when I need something even longer.

— MB

been using sticking broads for a long time ,it’s the only way to do most any molding. I have one that is for windows Mullins only. Mr Bickford knows his stuff. I go to that book often.