In all my years of messing about with old workbenches and their holding devices, I haven’t had much experience with the “bench knife.”

In its original form, the bench knife is nothing more than a broken piece of a dinner knife. It is used to secure boards on the benchtop for planing their broad faces. You first butt one end of your work against a stop of some kind. To secure the hind end of the board, you hammer the bench knife into both the benchtop and the end grain of the work.

Edward H. Crussell’s fantastic curmudgeonly “Jobbing Work for the Carpenter” (1914) describes it thus:

The bench knife is a tool of every-day use in Europe, but is not so well known or used in America. It is nothing but a piece of the blade of an old dinner knife about 1-1/4 or 1-1/2 in. long, and is used in lieu of a nail for holding material on the bench. It is used at the opposite end to the bench stop, being driven partly into the bench and partly into the material, as shown in Fig. 257.

For thinner stuff it is driven deeper into the bench. It is easy to apply, can be readily removed with a claw hammer, and does not mar the bench or material so badly as other forms of fastening. It is a good idea to have two or three of these bench knives because it is so easy to mislay them in the shavings.

Thanks to the worldwide butter knife shortage of 1915, ironmongers had to come up with a replacement to the simple broken knife. Most of the solutions that I see in books are a contrivance that drops into a row of bench dogs at the rear of the bench (who has a row of dogs on the rear of the bench?). Then you pull a lever that slides a thin piece of metal across the benchtop and into the end grain of the work.

I think there’s a reason that I have yet to see one of these devices in the wild: They were stupid. If you have a row of bench dogs, you could probably come up with a better way to hold the work than a mechanical doo-dad like the bench knife.

But today I saw a bench knife that I would buy and try.

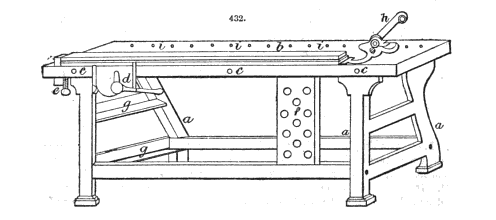

Advertised in a late 19th-century magazine, this bench knife clamps to the front edge of your workbench and is infinitely adjustable. The obvious downside to this thing is that benchtop thicknesses vary a lot (1-1/2” to 4” being typical). But beyond that detail, I think the thing looks pretty smart.

— Christopher Schwarz

Make sure benchcrafted does not see this!

Isn’t this eloquently handled by the batten?

I think you sent us off to The English Woodworker to show it off a couple of months ago.

Indeed it is. But I am open to exploring all manner of devices to come to a better understanding of them.

Plus, some people do not like holdfasts. Or they don’t have the strength to drive them in and out reliably. So I’m always looking for ideas and devices that I haven’t tried.

Chris

Thos. Syer’s patent was issued c.1883, and Griffin’s c.1885, so both inventions predate the worldwide butter knife shortage of 1915…

If you decide to raid the silverware drawer tonight, it might be prudent to make up some of those hide glue bandages beforehand. They may come in handy.

Don’t tell Rob Lee, he is already selling the ‘Veritas Bench Blade’ in a couple of models, and they have given him a patent on it. It even fits in a dog hole, but you don’t have to hammer it into the job to make it work.

So the question I’m asking is.. are there any of these mechanical bench stops in existence today?

I Intend to have holes at the back. I will mostly put holdfasts in them. And I intend to use a notched batten for this.

But I am also going to try using one of the horizontal bessey-toggle-on-a-post setups from veritas to do exactly this – and that would use the dog holes up front.

Stephan

Hello! I would like some direction from you. I want a solid foundation in woodworking. I just ordered your DvD “Mastering hand tools” . Is this a good place to start. I’ll probally get all of the DvD’s anyway. Just want to know the best place to start. Also If you don’t mind telling me what you think about this online school called Pennfoster. They offer Furniture making class’. I know you are a very busy person with the class teaching and the translating. Any input would be Golden. Thank you!

Sentrell,

I’m biased, but I think Robert Wearing’s “Essential Woodworker” is the best way to step into the craft and understand the tools an operations. And least for hand work.

I’m afraid I’ve never heard of Pennfoster. But I’m no expert on online schools. I’m a 45-year-old print-based fuddy-duddy.

New t shirt

“I’m a 45-year-old print-based fuddy-duddy”

Looks like a veritas hold fast on its side. Basically, Rob would only need a way to make a 3/4″ ID sleeve that clamps to the edge of the bench. Maybe just weld it to the top of an ad clamp?

Either way, still feels like overkill…

‘F’ clamp.

Stupid auto-correct.