With all the super-tuned, high-angle planes on the market today, you might think that scraper planes are a vestigial organ of the pre-bevel-up-plane era.

After all, once you get a handplane’s pitch up above 60°, tear-out tends to be a non-issue, right?

Well, not in my experience. I’ve found that high-pitch planes are indeed a great weapon against tearing, but there are still times when nothing but a scraper will fix what ails you.

This weekend I’m finishing up construction of the first reproduction of a walnut Shaker sitting bench from the White Water community in Ohio. The bench is simple in form, but difficult in size. The original is more than 13′ long and 12″ wide. The seat itself is one solid piece of 1″ walnut.

Thanks to the kindness of others, we managed to score enough walnut for two copies of the bench, which we’ll be donating to the Friends of White Water Shaker Village, the caretakers of this historical treasure.

The walnut for this first bench came from a farm about 10 miles away from the Shaker village, which is a nice codicil to the project. While the wood itself dropped into our lap, working with it has been a challenge. This walnut tree must have had a difficult life. Along the 13′ length, the grain reverses dramatically at least six times. There are knots to deal with, and I would guess that the tree must have grown at an angle – there is some definite tension stored up in the grain.

So getting the components roughed out to size has been arduous. The wood wanted to crook something fierce. The wider pieces also cupped. Today I started surfacing all the parts and found that the grain was too wild for even a freshly sharpened 62°-pitch plane with a tight mouth. And things got worse after I glued the aprons to the seat – leveling the seam between the aprons and the seat gave every handplane I own fits.

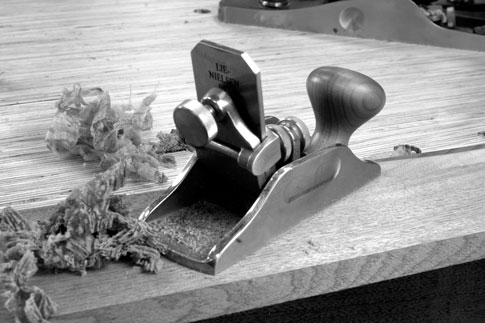

So I picked up my small scraper plane, which is based on the Stanley No. 212. I love this little bugger. I have no idea why the original Stanley plane is so rare. I have found the plane to be robust, easy to adjust, comfortable to use and ultimately effective against tearing.

And, true to form, the little scraper cleaned up all the messes that my handplanes had made. One of its biggest assets is its small size – it’s like a smallish block plane. That means it will get into small hollows and scrape them with ease. But unlike a card scraper, it won’t leave a dished surface that will look ugly once you put a film finish on it.

And, most importantly, the little scraper plane kept me from having to grab the pneumatic sander, which someone in our shop had left lying out in plain view. I felt the yellow DA sander mocking me while I was cursing the tear-out scattered like buckshot all over my work. But who’s laughing now, windbag tool?

— Christopher Schwarz

Windbag tool? Always enjoyable reading your blogs…….including all the very usable woodworking info.

Maybe a scarce plane because of the #80 scraper doing the same thing but cheaper? Or is there a big difference?

Chris, How do you address the iron on that scraper plane?

Do you hone and then roll a hook?

Frank

chris, are you suppose to relieve the corners on a scraper plane? keep up the great information, i enjoy reading it and learning.

mike

Chris,

Could you comment on the process for tuning and adjusting a scraper plane?

Thanks!

Frank G.